SF-2781E Stretch Film Dispenser

from 28.64 € tax incl.

Sign up to be notified when the product is available again.

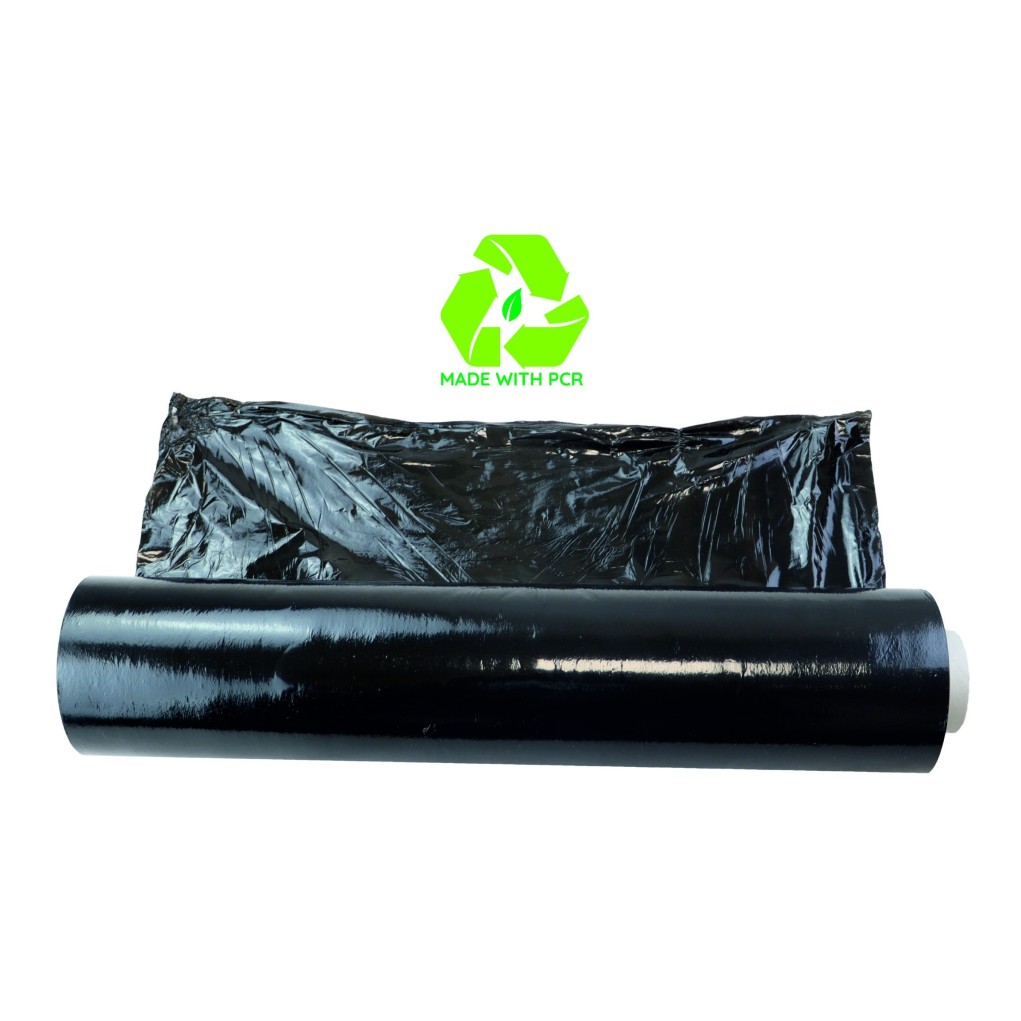

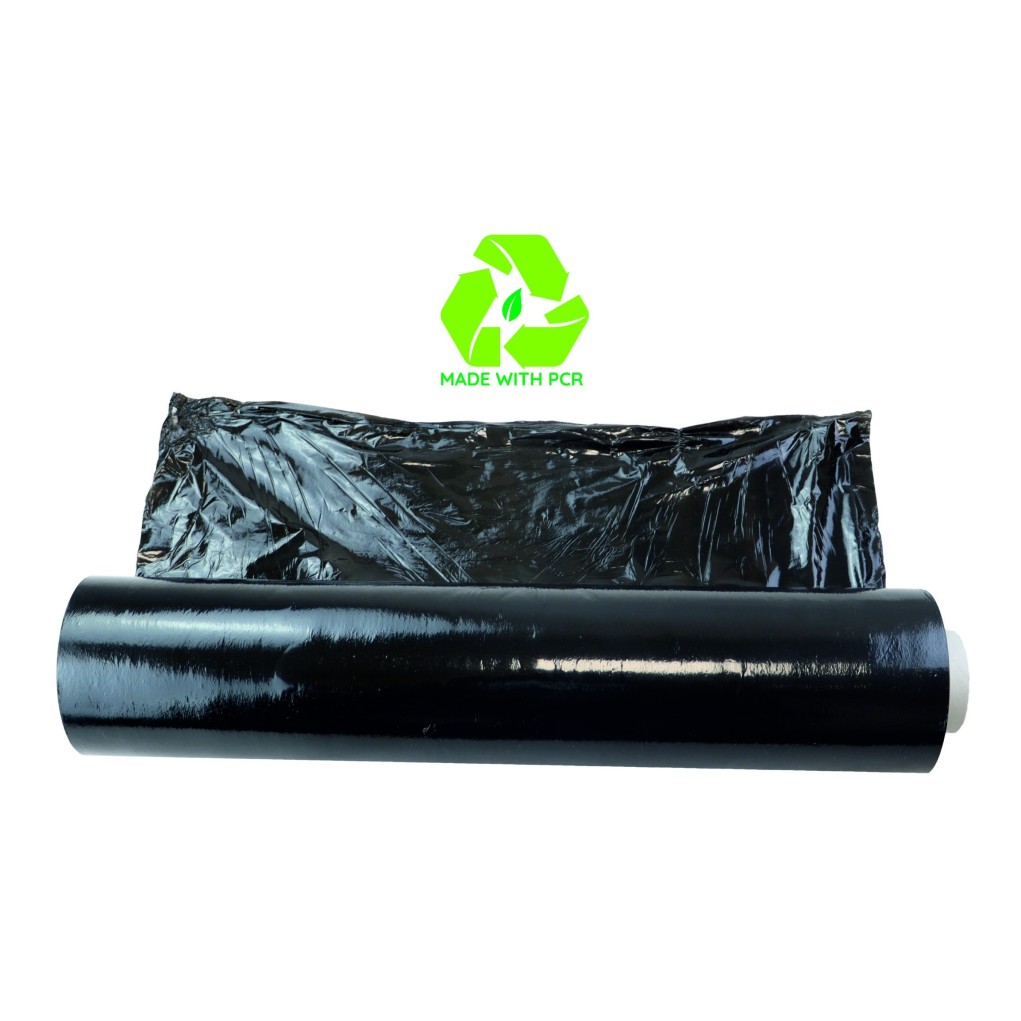

ecoSTRETCH This is a modern, black stretch film with a thickness of 23 µm, created with the safe packaging of goods and care for the environment in mind. Made 100% from PCR regranulate, it combines high quality and durability with ecological responsibility. Ideal for daily use in warehouses, transport and logistics.

PCR (Post Consumer Recycled) it is a secondary raw material obtained from waste from plastics that have gone through a usage cycle - mainly packaging and foils used by consumers. These materials are collected, sorted, washed and processed in the form of regranulate, which then goes back into production m.in. stretch film.

Using PCR plastic in packaging production is a real step towards circular economy. Thanks to this technology:

By choosing stretch film made from PCR, not only you secure your goods, but also you support sustainable production and you limit the negative impact of the company's activities on the environment.

Stretch film is an extremely stretchable film made of plastic LLDPE. The presented model ecoSTRETCH it is made 100% from raw material PCR (regranulate derived from recycling), making it an exceptional choice for environmentally conscious companies. Thanks to its properties, it ensures wrapping, stabilization and protection of the cargo even in demanding transport conditions.

Both foils perform the same protective functions, but they differ in terms of their impact on the environment. See why it's worth choosing the PCR variant:

PCR film is the choice of modern companies that want to combine packaging efficiency with care for the planet.

In our set we used black stretch film with a thickness of 23 µm - ideal for professional securing of heavier loads requiring the highest durability and protection.

from 28.64 € tax incl.

from 4.77 € tax incl.

from 2.88 € tax incl.

from 7.40 € tax incl.

from 11.93 € tax incl.

from 0.52 € tax incl.

from 4.06 € tax incl.

from 5.59 € tax incl.

from 2.11 € tax incl.

from 11.93 € tax incl.

from 0.81 € tax incl.

from 1.67 € tax incl.

from 0.81 € tax incl.

from 5.97 € tax incl.

from 9.43 € tax incl.

from 7.16 € tax incl.

from 4.20 € tax incl.

from 28.64 € tax incl.

check_circle

check_circle

Please verify the country of delivery and form of purchase in the customer panel. The data provided in the customer panel differs from the currently set data.

Change settingsWe have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.