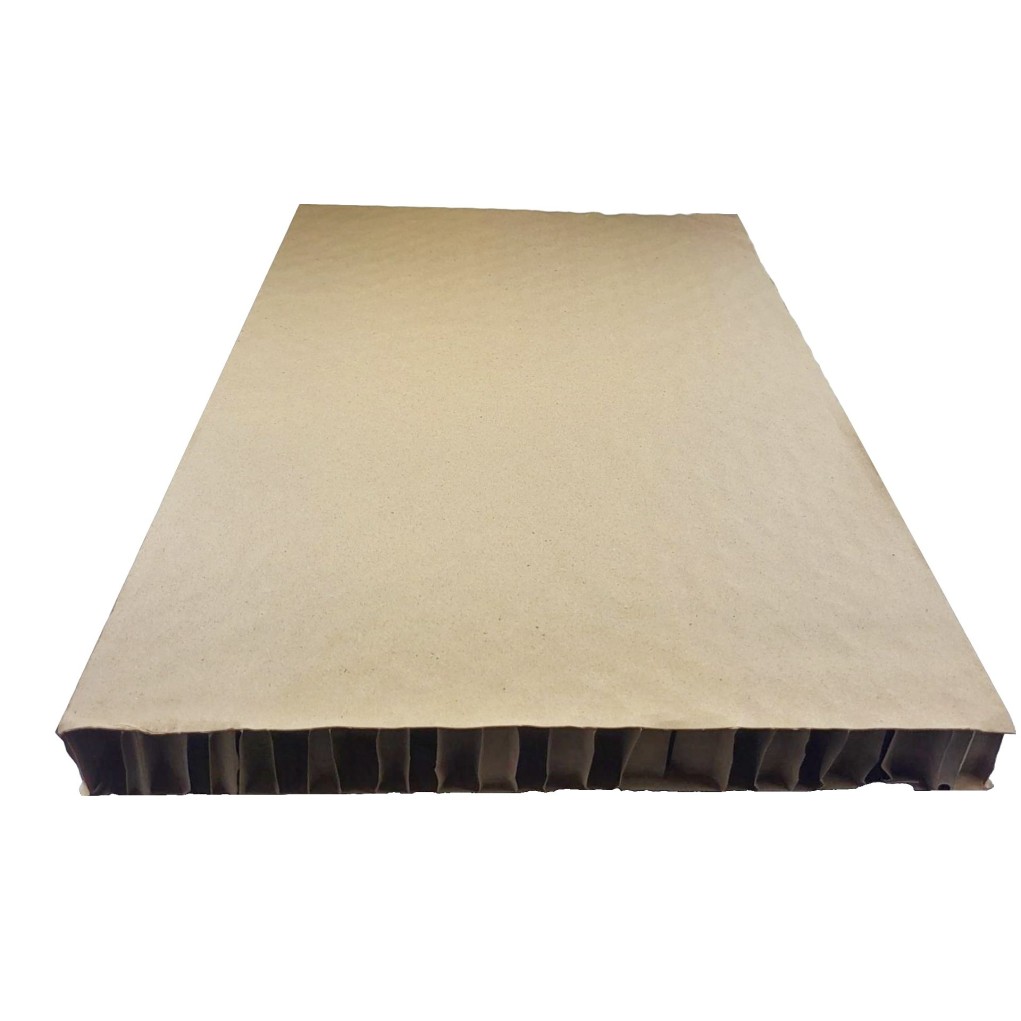

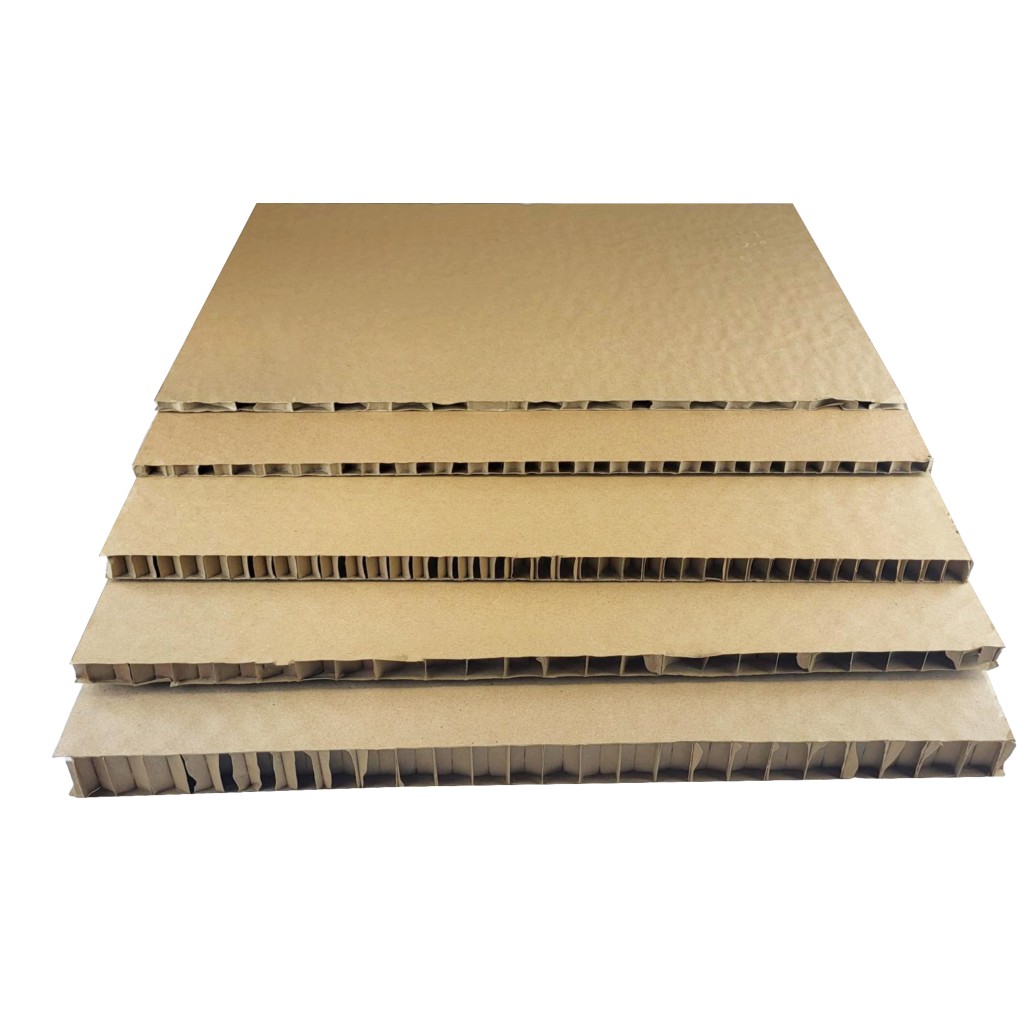

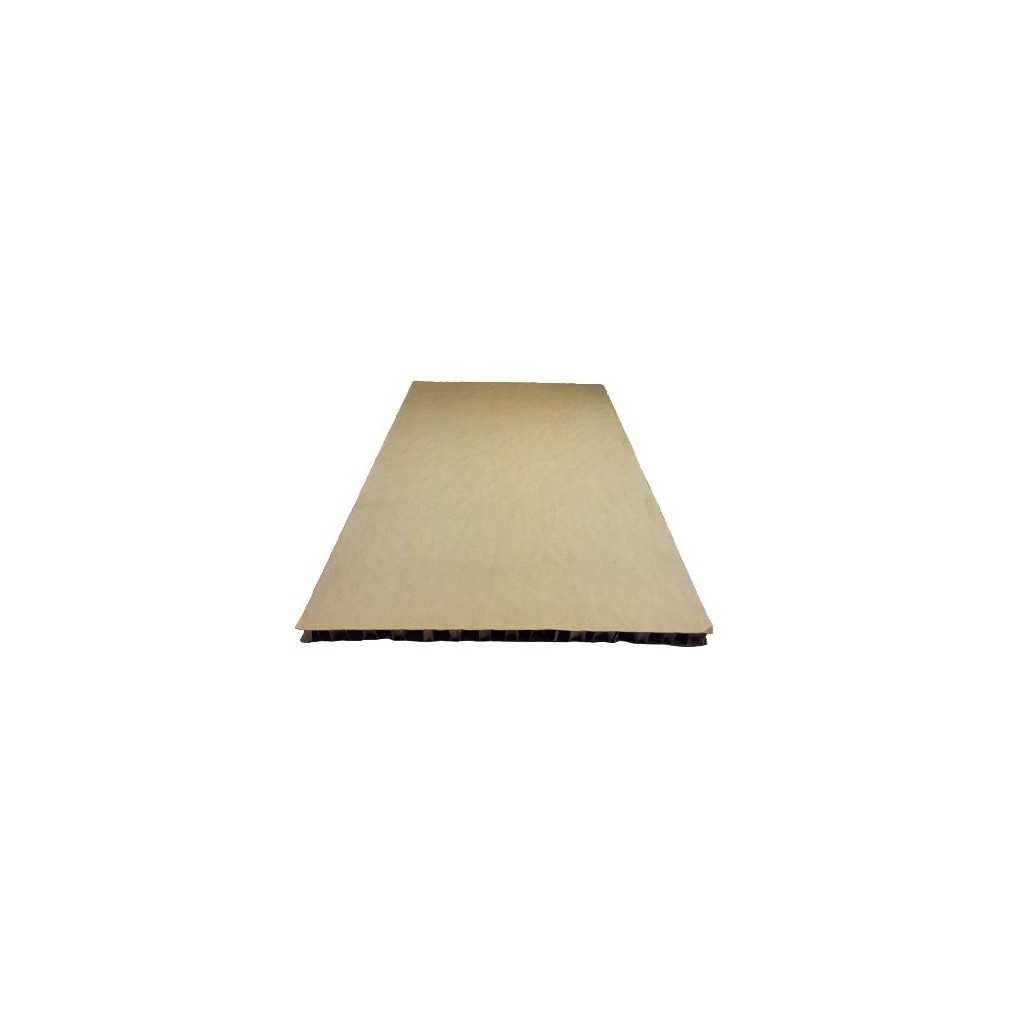

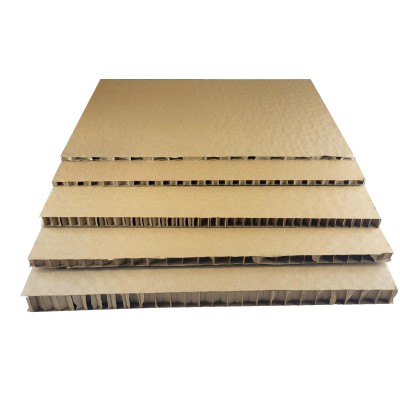

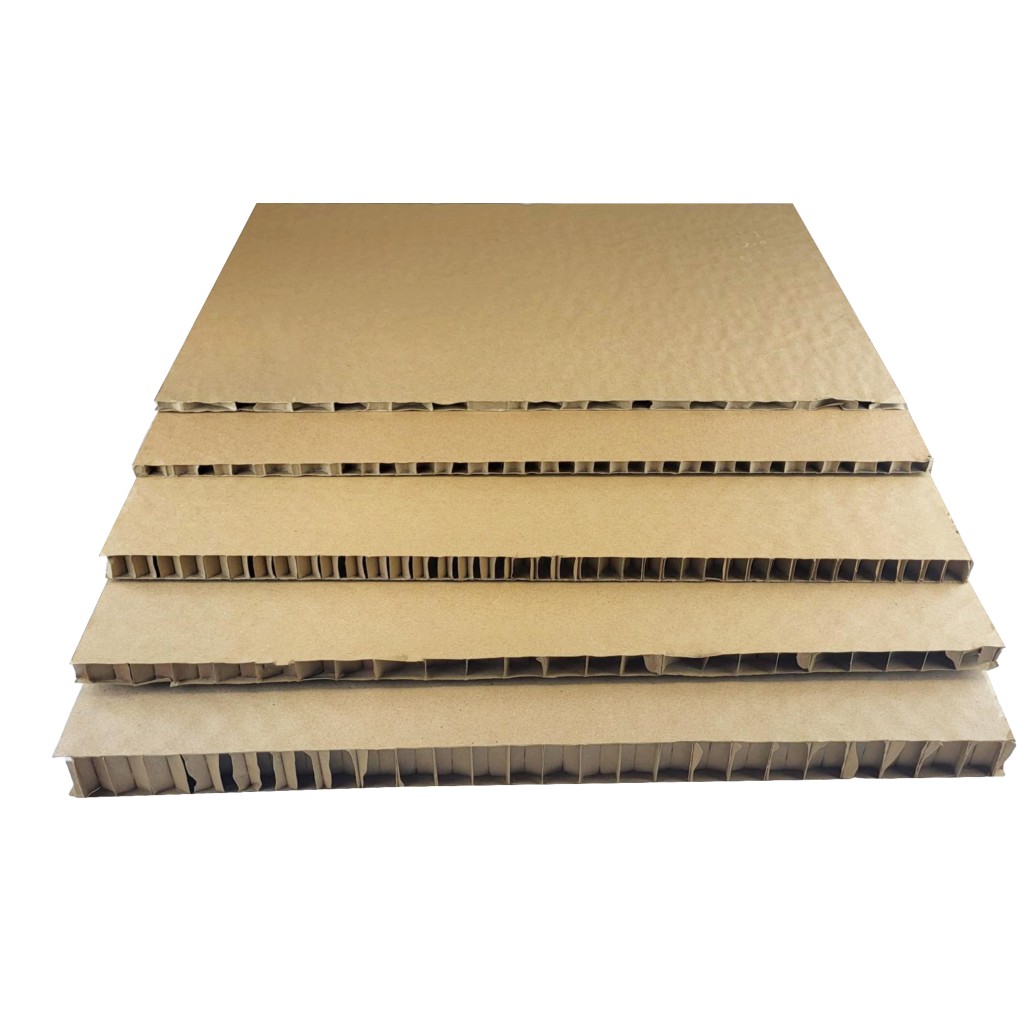

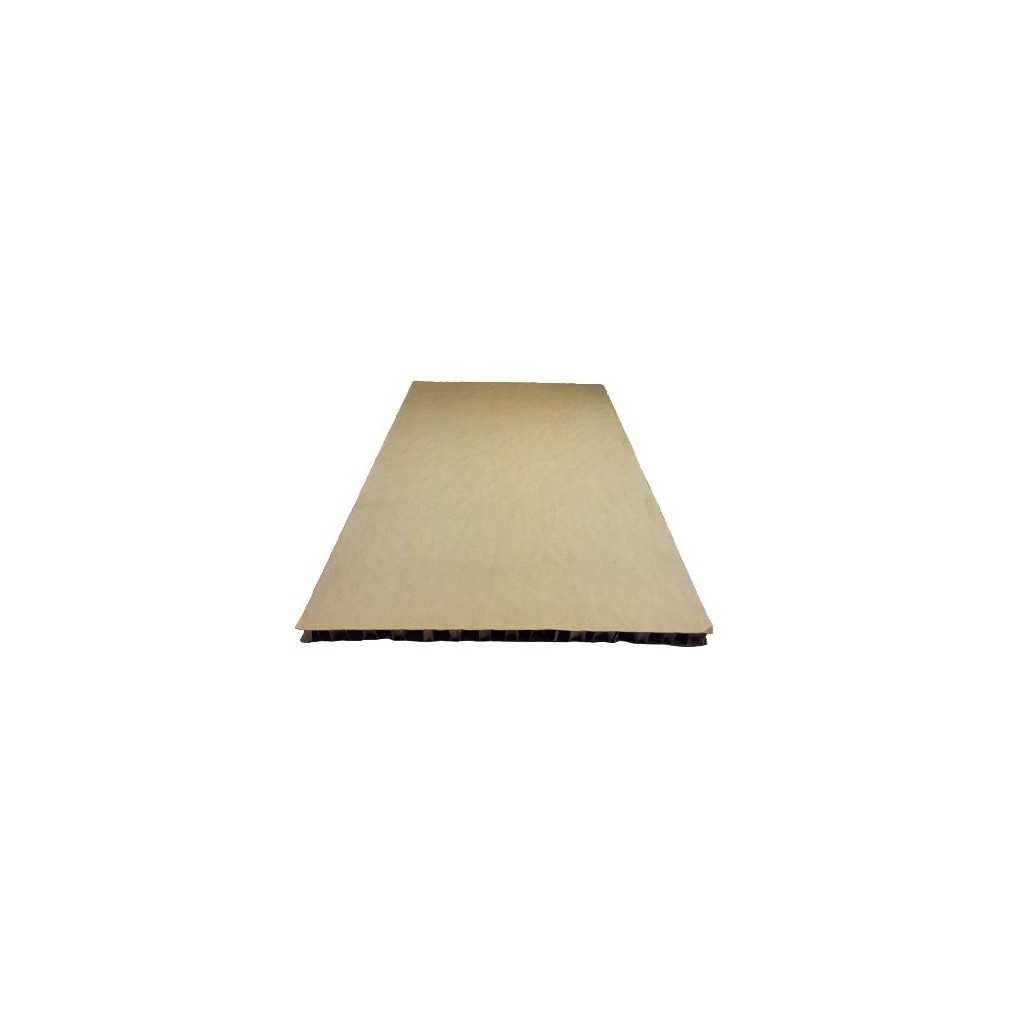

"Honeycomb" Cardboard Sheet 600 × 400 × 50 mm - Maximum Thickness, Maximum Protection

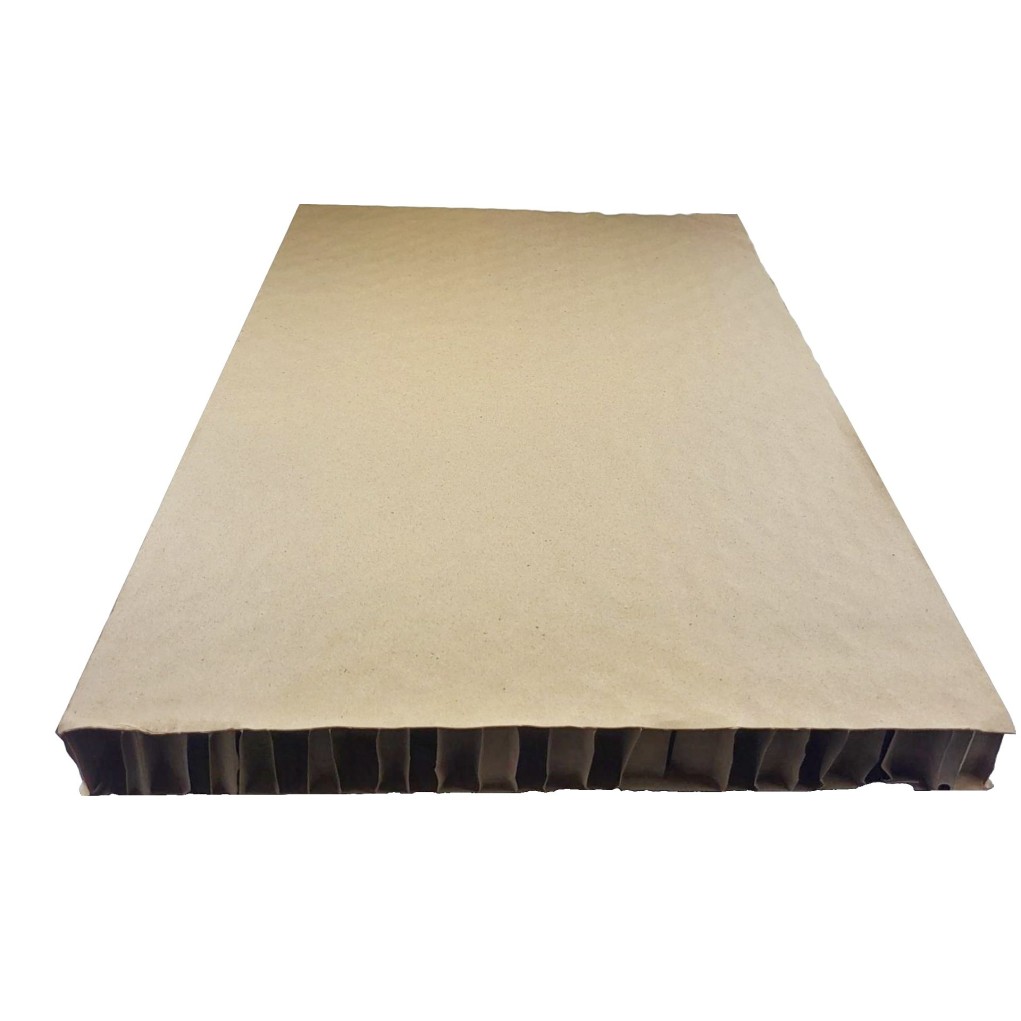

"Honeycomb" paper structure - a fifty-millimeter core of densely arranged hexagonal cells and two precisely matched layers of testliner - create an absolutely rigid, yet surprisingly light crush-resistant, puncture-resistant and long-lasting vibration plate. Despite its impressive height of 50 mm, a single sheet is more than ten times lighter than a wooden board of the same thickness; after use, it goes directly into the waste paper stream. The 600 × 400 × 50 mm format is an ideal "bumper" and liner for high-value & heavy-duty loads, where both damping and load capacity matter.

🍯 What exactly is a "honeycomb" structured sheet?

Honeycomb sheet is made in three stages:

- Core expansion – strands of kraft paper glued with water starch adhesive are wound into a block and stretched, creating a regular, 50-millimeter hexagonal network, which gives the plate spatial stiffness.

- Laminating covers – a testliner (high gram paper from recycling) is applied on both sides, transferring tensile and compressive stresses just like the straps of a double T-beam.

- Cutting to format – the finished plate is laser-cut or tape-cut to 600 × 400 mm with a tolerance of ± 1 mm, which guarantees repeatability in automatic packaging lines.

- 🔬 Base material: 100% kraft paper (from recycling) + solvent-free starch adhesive.

- 🪶 Surface weight (50 mm): approx. 2.25 kg/m² – still lighter than PE foam 30 kg/m³ of the same thickness.

- 📊 Core parameters: height 50 mm · mesh 15 mm · wall thickness 0.20 mm.

- 🌍 Ecology: fully biodegradable, compostable and recyclable in the waste paper stream.

🧪 Key properties – stiffness + damping

A thickness of 50 mm places the sheet in the absolute heavy-duty class: it combines the load capacity of a wooden beam with the damping of closed-cell foam, while remaining paper-light.

- 🏋️♂️ Static load capacity up to 2,400 kg/m² – allows stacking pallets without additional wooden inserts, even with multi-week storage.

- 📏 Minimal deformations – stiffness in the Z-axis exceeds PE foam by 97%, limiting corner crumples and bending arrow during long routes.

- 💥 High impact absorption – the 50 mm core absorbs the energy of a fall from 1.8 m, effectively protecting glass, marble, precision electronics and heavy battery modules.

- 🔄 Multiple uses – after removing the load, it recovers ≈ 85% of the thickness in ≤ 30 s, so it can go through several full transport cycles.

- 🪶 Radical weight saving – 2.25 kg/m² vs ≈ 25 kg/m² for a 50 mm pine board: lower freight costs, smaller CO₂ footprint and easier manual handling.

The end result? One sheet replaces thick wooden boards + a layer of PE foam, speeding up packaging and simplifying the recycling process.

💧 Resistance and safety

- 🌡️ Stable in −20 °C … +70 °C – does not crack in frost, does not deform on a heated ramp.

- 🌧️ Short-term moisture doesn't harm – the sheet maintains parameters with temporary moisture; it is not intended for constant water bathing.

- ⚡ ESD version on request – antistatic coating protects electronics from discharges.

- 🍏 Contact with food (indirect) – paper and starch glue are odorless; there is no certificate for direct contact with food.

- 🔥 Clean burning – < 1 % ash, zero toxic gases, high energy recovery in the incinerator.

📦 Typical uses – how you can benefit

- 📑 Ultra-heavy liners – stabilize layers of castings, engines, transformers and battery packs.

- 🔄 3D spacers – you crease wedges and frames blocking elements weighing 1 t + during sea transport.

- 🫧 Protection of stone plates & XXL glass – 30 mm marble, 12 mm facade glass, quartz sinter 320 × 160 cm.

- 🛡️ 50 mm angles – protect stone countertops, premium furniture fronts and oversized laminated doors.

- 📦 Eco-insert e-commerce heavy – 300 l aquariums, class A hi-fi amplifiers, laboratory equipment.

- 🏗️ XXL event modules – detachable stage walls 3.5 m, assembly without tools, 30 % cheaper freight compared to MDF.

- 🪑 Premium ultralight furniture – filling countertops and 60 mm doors reduces weight by 40%, facilitating assembly and logistics.

🏭 Industries already using 50 mm thickness

- 💻 Electronics & Optics - 98″ screen separators, HPC server chassis, DSP cabinets.

- 🚗 Automotive & Aerospace - engine spacers, composite wings, EV battery packs.

- 🪨 Stonemasonry & Premium Countertops - transportation of granite, quartz and large-format sintered products.

- 🍾 Premium Beverages and Foods - 15 l barrel nests, 12 kg jars, crystal carafes.

- 🥼 Medical & Laboratory Equipment - tomographs, climatic chambers, standing spectrometers.

- 🎨 POS Systems & Scenography - reusable display modules and 4 m trade show walls.

⚖️ Comparison with PE foam

| Criterion |

"Honeycomb" 50 mm |

PE Foam 50 mm |

| Composition |

100 % paper + water glue |

LDPE Polyethylene |

| Surface mass |

≈ 2.25 kg/m² |

≈ 3.5 kg/m² |

| Load-bearing capacity / stiffness |

Up to 2 400 kg/m² (very high) |

Mainly damping (low stiffness) |

| Recycling / disposal |

Blue container ♻️ (waste paper) |

LDPE 4 collection → washing + regranulation |

| Biodegradability |

Yes |

No |

| Carbon footprint |

Low (paper) |

High (petroleum-derived) |

If you are looking for PE foam sheets, check out our

full offer ➜

⚙️ Technical Specifications

- Material: testliner paper + kraft (100% recycling)

- Dimensions: 600 mm × 400 mm × 50 mm

- Surface weight: ≈ 2.25 kg/m²

- Static load capacity (BCT): 2,400 kg/m²

- Thermal conductivity λ: 0.045 W/(m·K)

- Operating temperature range: -20 °C ... +70 °C

- Recycling code: PAP 20

- EAN: 5905489972266

♻️ Recycling and reuse – closing the loop

- 🗑️ Sorting without guessing – throw it in the blue bin, along with cardboard and newspapers.

- ♻️ Full loop closure – the paper mill turns the fiber into new cardboard within a few days.

- 🔄 Second life in the warehouse – thanks to recovery, the sheet serves as a spacer for several cycles.

- 🌱 Industrial compost – decomposition into humus within a few weeks.

- 🔥 Energy without toxins – combustion < 1% ash, high heat recovery.

📦 Custom-sized boxes and packaging personalization

Connect a perfectly cut cardboard to a 50 mm sheet to create all-paper packaging: no plastic, single recycling fraction, highest level of transport protection.

- 🔒 Zero clearance – the format + box eliminate empty spaces, the goods do not "fly" during the journey.

- 🌍 Zero plastic – the customer throws everything into the waste paper, without dividing the fraction.

- 💡 Strong branding – inside/outside printing, paper look supports eco-image.

- 📦 Less volume = lower freight – compact packages improve logistics economics.

- ♻️ One waste fraction – higher recycling at the recipient, no penalties for plastic.

Take advantage of

Custom-sized Boxes

, and for personalization, choose

Boxes with print

.

📞 Bulk orders and advice

Do you need a different thickness, mesh size, or coating? Contact us – we will set the parameters (mesh 8–25 mm, weight 150–350 g/m², hydrophobic or ESD coating) and prepare an offer tailored to your volumes.

Fun facts:

- 🧊 Hydrophobic and self-extinguishing – a special version meets the B-s1,d0 flammability class and repels water (Cobb 60 ≤ 25 g/m²).

- 📊 80% air – an empty, hexagonal core guarantees the best weight-to-capacity ratio in the world of paper fillings.

- 🔧 Parameters on request – mesh 8–25 mm, faces 150–350 g/m², thickness 10–50 mm; carrying capacity up to 2 600 kg/m².