Brown flap cardboard K020 BC 600x400x400

from 11.57 zł tax incl.

| Quantity | Price tax incl./tax excl. |

|---|---|

| > 1 szt. | 4.17 zł 3.39 zł |

| > 120 szt. | 3.96 zł 3.22 zł |

| > 180 szt. | 3.84 zł 3.12 zł |

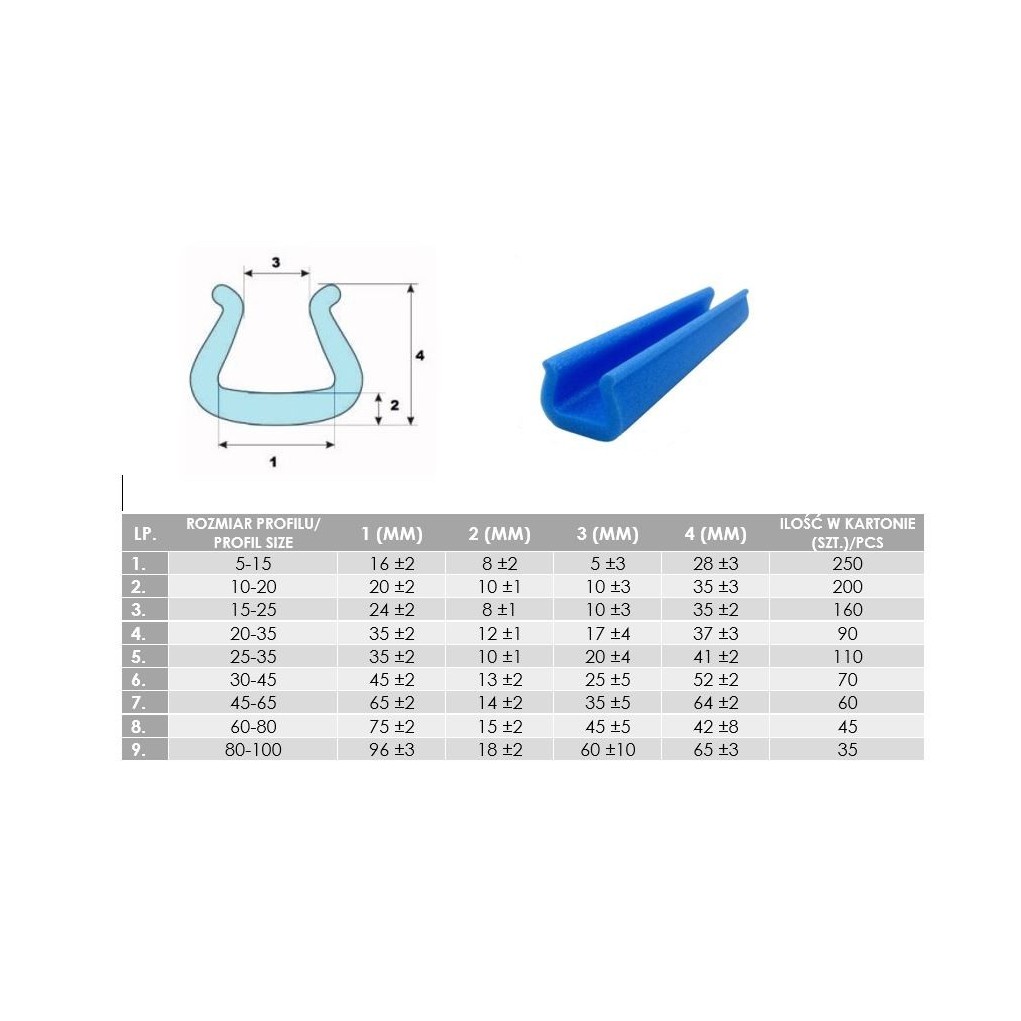

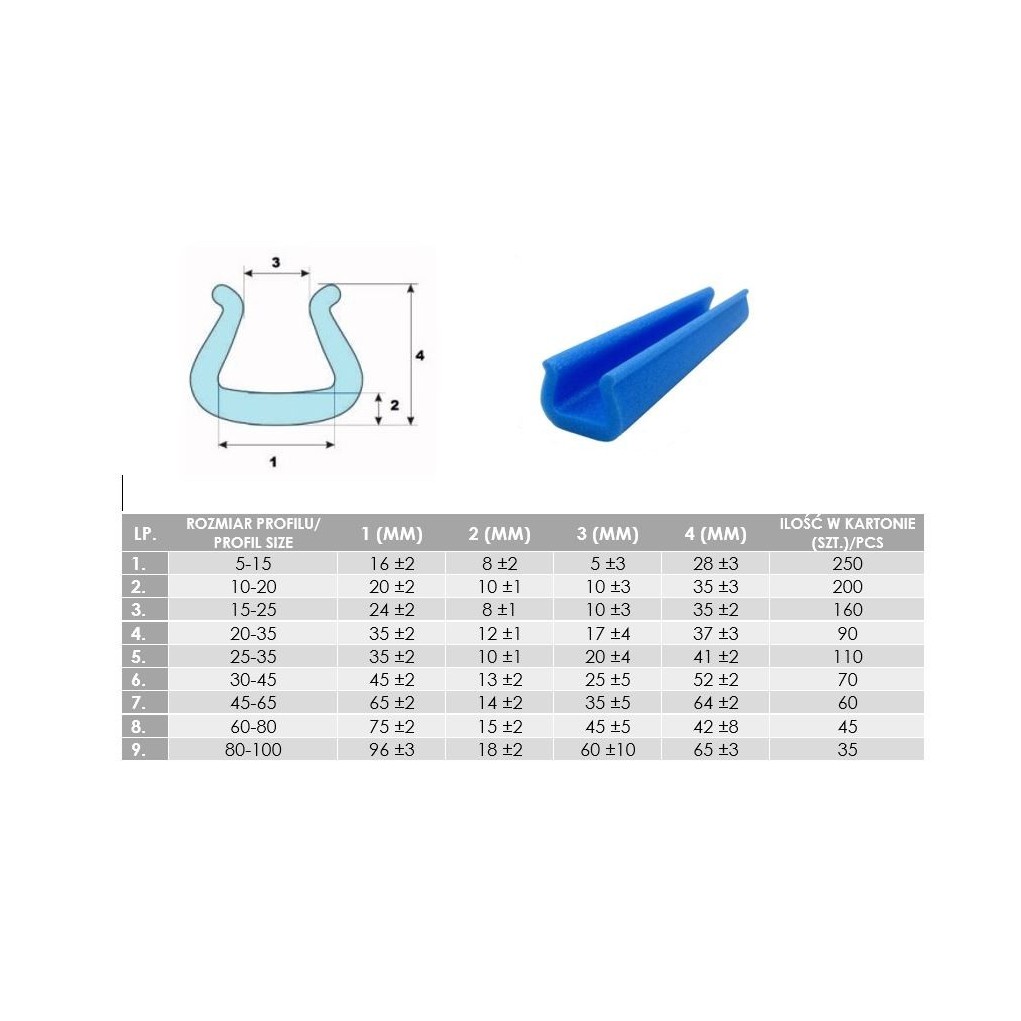

"U 45-65" is the widest foam profile available from Boxmarket. It protects the edges of elements with a thickness of 45 - 65 mm: 50 mm stone countertops, large-format staircase steps, XXL quartz sinter, 60 mm facade glass panes and massive premium class door wings. Despite the huge throat, a one-meter section weighs only ≈ 25 g, so it does not inflate freight costs. Closed-cell PE foam behaves like a network of micro air cushions, absorbs shocks and eliminates edge chipping. The characteristic blue color facilitates quality control at every stage of the supply chain.

"U" shaped profile is created in the process of extruding foamed polyethylene (EPE/LDPE). The widest throat "U 45-65" automatically clamps onto edges 45 - 65 mm and provides three key functions:

In 3PL centers, the profile drastically shortens the packing of heavy components, replacing multi-layer bubble wrap.

The table below compares LDPE foam profiles and solid cardboard corners:

| Aspect | LDPE Foam Profile | Cardboard Corner |

|---|---|---|

| Material / production | Foamed LDPE, continuous extrusion. | Layered KRAFT paper, "V" profile. |

| Protection / damping | Soft damping; no load bearing. | Rigid protection; less elasticity. |

| Weight / volume | ≈ 25 g/m; arms 20 mm. | ≈ 190 g/m; wall 3 mm. |

| Resistance to moisture | Hydrophobic LDPE. | Hygroscopic paper; PE coated version. |

| Ecology / recycling | LDPE #4 recycling. | Biodegradation or waste paper. |

| Palletizing | Does not carry weight. | Carries loads – stacking. |

Looking for cardboard corners? Check out our full offer ➜

Fill in the "U 45-65" profiles with PE foam sheets and cardboard dividers to create a complete protection system:

Creator foam sheets - specify dimensions (10 - 50 mm) and color, and you will immediately see the price:

The creator cardboard dividers allows you to choose the format, number of layers and grammage:

Do you pack massive countertops, stone slabs or glass up to 65 mm thick? Contact the Boxmarket team - we will prepare an offer for U 45-65 profiles and match PE sheets and cardboard dividers so that your supply chain is fast, safe and economical.

from 11.57 zł tax incl.

from 9.84 zł tax incl.

from 7.06 zł tax incl.

from 7.06 zł tax incl.

from 982.77 zł tax incl.

from 59.04 zł tax incl.

from 0.95 zł tax incl.

from 0.82 zł tax incl.

from 122.99 zł tax incl.

from 7.06 zł tax incl.

from 3.27 zł tax incl.

from 198.34 zł tax incl.

from 47.33 zł tax incl.

from 6.14 zł tax incl.

from 3.47 zł tax incl.

from 19.77 zł tax incl.

from 6.56 zł tax incl.

from 0.48 zł tax incl.

from 2.09 zł tax incl.

from 23.63 zł tax incl.

check_circle

check_circle

Please verify the country of delivery and form of purchase in the customer panel. The data provided in the customer panel differs from the currently set data.

Change settingsWe have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.