Brown flap cardboard K020 BC 600x400x400

from 11.57 zł tax incl.

| Quantity | Price tax incl./tax excl. |

|---|---|

| > 1 szt. | 1.46 zł 1.19 zł |

| > 100 szt. | 1.43 zł 1.16 zł |

| > 200 szt. | 1.39 zł 1.13 zł |

| > 300 szt. | 1.35 zł 1.10 zł |

| Pallet | 1.21 zł 0.98 zł |

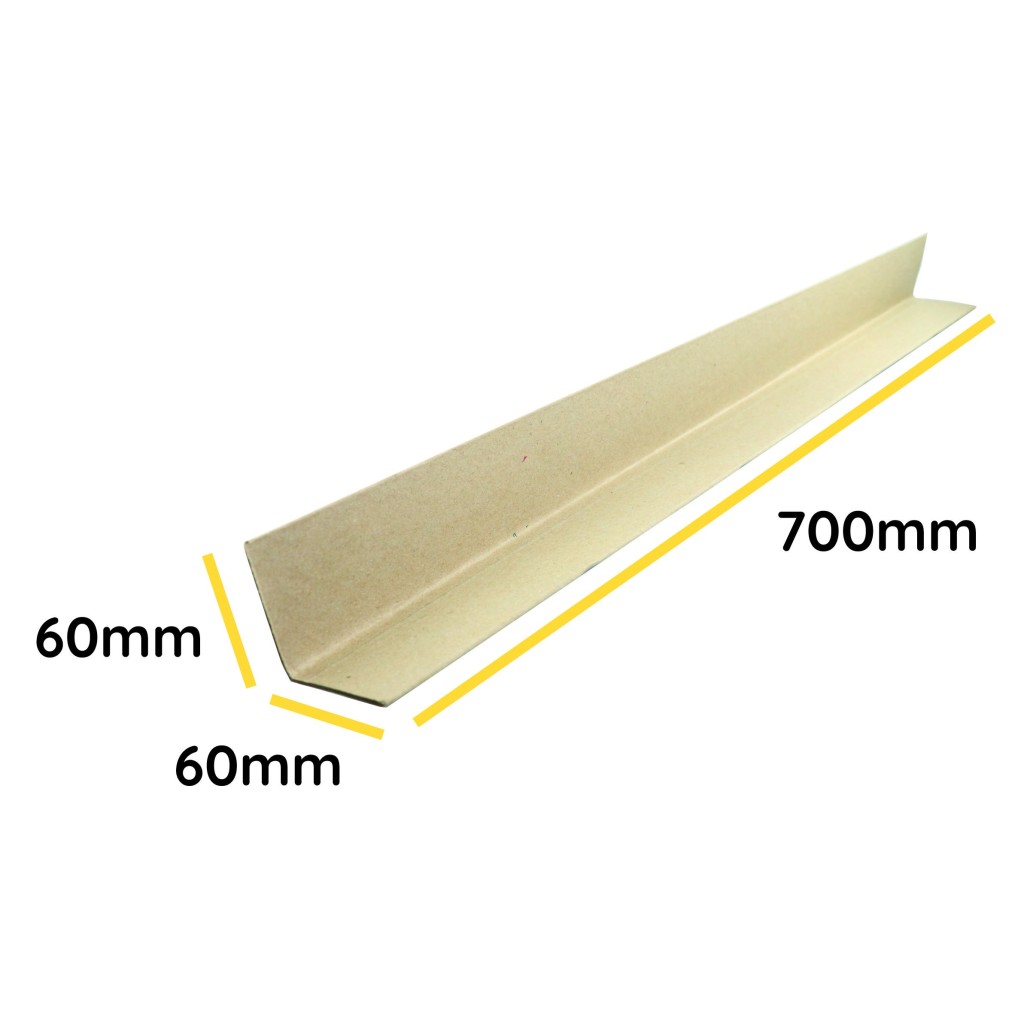

Three millimeters of solid cardboard on each side of the angle create an extremely durable barrier for heavy and bulky loads. The 60 × 60 mm arms distribute the pressure of strapping tapes and stacked pallet weight over a huge corner area, eliminating point crushes. The 700 mm section covers a larger part of the edge, so even an 80 cm high cardboard will not deform during transport. One piece weighs only ≈ 0.17 kg, and the natural brown (KRAFT paper) emphasizes the ecological character. Ideal for bricks, bags of cement, wood-based panels, industrial machines and XXL furniture ⭐.

The 60 mm heavy-duty profile allows for safely pressing the PET tape 16–19 mm with a force > 1000 N, stacking pallets of cellular concrete blocks, and stabilizing large POS displays. In combination with PE foam sheets and cardboard inserts, it creates a modular protection system that drastically reduces the number of complaints and lowers packaging costs.

Cardboard angle is a protective "L" shaped profile that covers two planes of the packaging and the corner itself. Made of multi-layer solid cardboard, the 3 × 60 × 60 mm profile creates a structural beam - it absorbs compressive forces during strapping with steel tape, forklift transport and stacking.

A length of 700 mm protects most of the height of popular cartons and IBC barrels, increasing the load's resistance to wobbling. Installation is lightning fast: place four (or eight) profiles in the corners of the pallet before wrapping with stretch film. After unloading, the angles can be easily removed, stacked and reused or recycled.

The profile is made from glued layers of high-density KRAFT solid cardboard. Laminating sheets at a 90° angle provides a rigid structure resistant to compression and impact, while maintaining low weight and full biodegradability.

On the BÖWE RollCorner line, three KRAFT tapes are glued with PVA-D3 adhesive, wrapped at a 90° angle, pressed with a force of 4 t/m and dried in an 80 °C tunnel. The "V" 60 mm profile stabilizes for 12 hours, after which it is cut with a laser guillotine into precise 700 mm sections. Each batch undergoes an ECT > 420 N test, moisture measurement and 3D angle scan ±0.4°.

The angle goes into the PAP 20 fraction. Fibers and thermal energy from glue are recovered in the paper mill. In case of contamination, it can be burned in an energy recovery boiler - it only emits CO₂ and water vapor.

The following table compares the cardboard corner (construction) and LDPE foam profile (damping):

| Aspect | Cardboard Corner (solid cardboard) | Foam Profile (LDPE) |

|---|---|---|

| Material and production | Multi-layer KRAFT paper, “V” profile, renewable raw material; optional PE coating. | Foamed LDPE, continuous extrusion, petrochemical raw material. |

| Protective properties | Rigid protection, disperses pressure; less shock absorption. | Soft damping, suppresses vibrations; lack of structural load-bearing capacity. |

| Weight and volume | ≈ 170 g/unit; 3 mm wall → small size increase. | ≈ 5–10 g/unit; wall ≥ 10 mm → larger transport volume. |

| Resistance to moisture / chemicals | Hygroscopic; PE coating = hydrophobic, oil-resistant. | Hydrophobic, chemically neutral without coatings. |

| Recycling / ecology | Biodegradable or waste paper; low carbon footprint. | Recycling LDPE #4; non-biodegradable. |

| Typical uses | Heavy materials, bricks, bags, boards, XXL furniture. | Delicate items, glass, electronics. |

| Palletizing / stacking | Transfers weight – safe stacking. | Does not transfer weight – only damping. |

If you are looking for PE foam protection profiles, check out our full offer ➜

In addition to the ready-made corner protectors, order PE foam sheets and cardboard dividers, creating a layered protection system tailored to your logistics.

In the foam sheet creator, you provide the length, width and thickness (10–50 mm) as well as the color - online price in a second. The sheets serve as:

The cardboard dividers creator allows you to choose the format, number of layers and grammage. Application:

Packing bricks, bags of cement, OSB boards or XXL furniture in large volumes? Contact us - we will prepare a pallet offer for 60 × 60 × 3 mm angles, 700 mm long (or other dimensions) and we will select PE foam sheets and cardboard dividers for your logistics, so that the entire supply chain is fast, safe and economical.

from 11.57 zł tax incl.

from 11.81 zł tax incl.

from 7.06 zł tax incl.

from 7.06 zł tax incl.

from 47.33 zł tax incl.

from 1.18 zł tax incl.

from 4.96 zł tax incl.

from 92.25 zł tax incl.

from 7.06 zł tax incl.

from 174.35 zł tax incl.

from 49.14 zł tax incl.

from 6.14 zł tax incl.

from 3.68 zł tax incl.

from 220.17 zł tax incl.

from 5.10 zł tax incl.

from 22.95 zł tax incl.

from 122.99 zł tax incl.

from 11.29 zł tax incl.

from 157.44 zł tax incl.

from 3.87 zł tax incl.

check_circle

check_circle

Please verify the country of delivery and form of purchase in the customer panel. The data provided in the customer panel differs from the currently set data.

Change settingsWe have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.