Brown flap cardboard K020 BC 600x400x400

from 1.79 € tax incl.

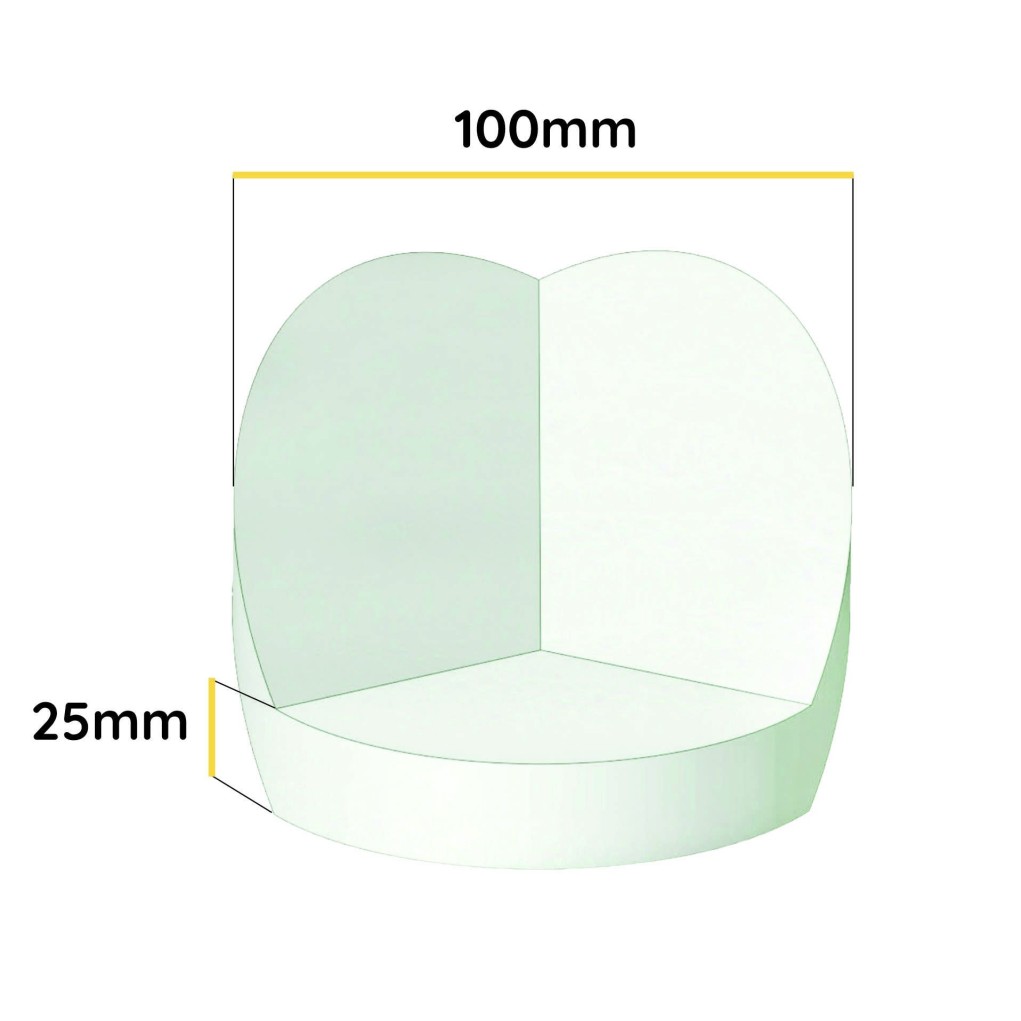

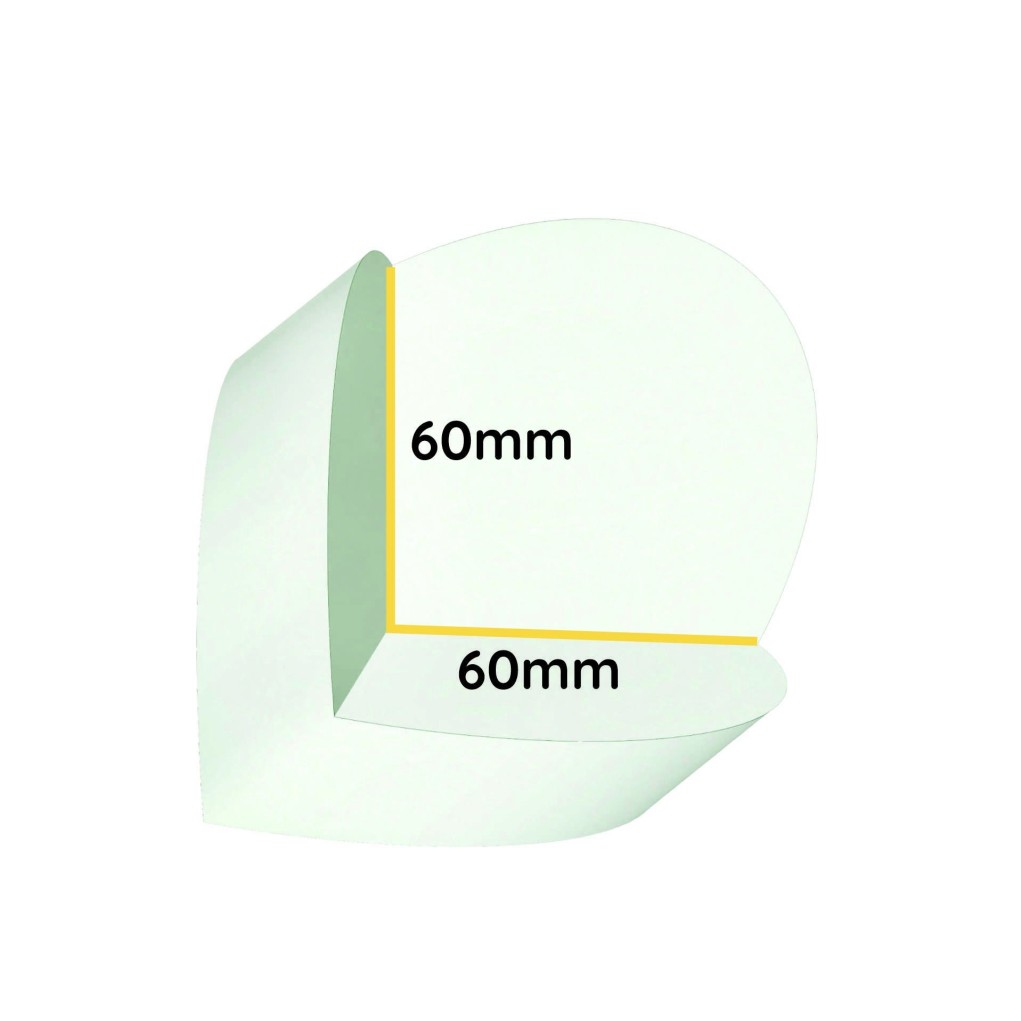

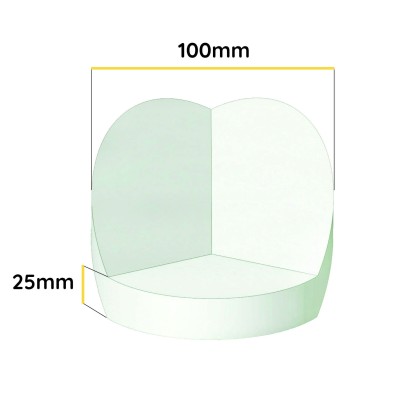

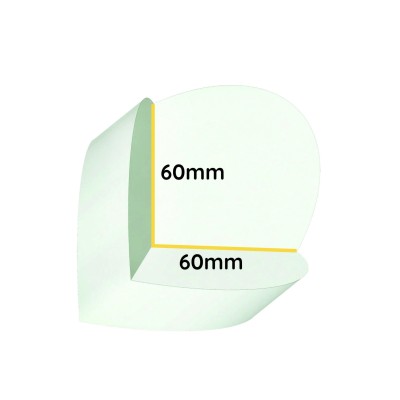

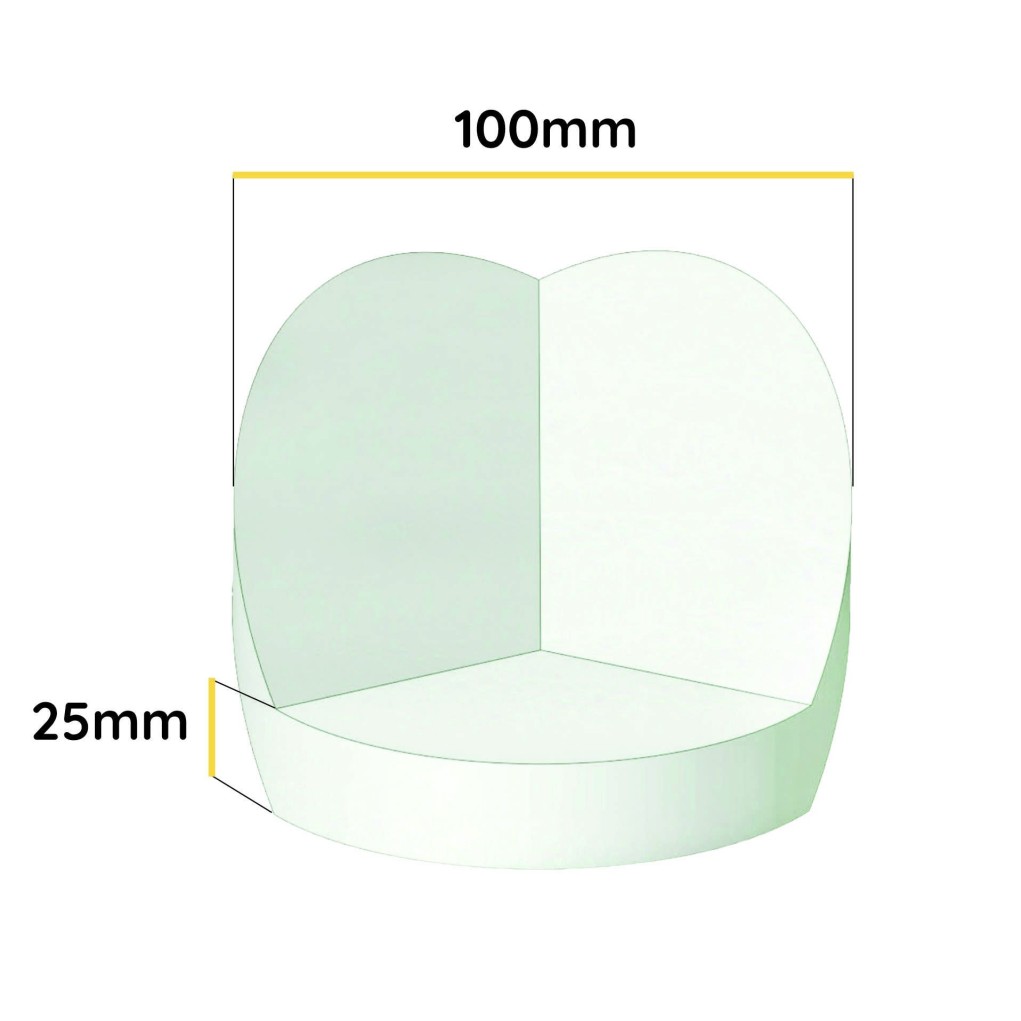

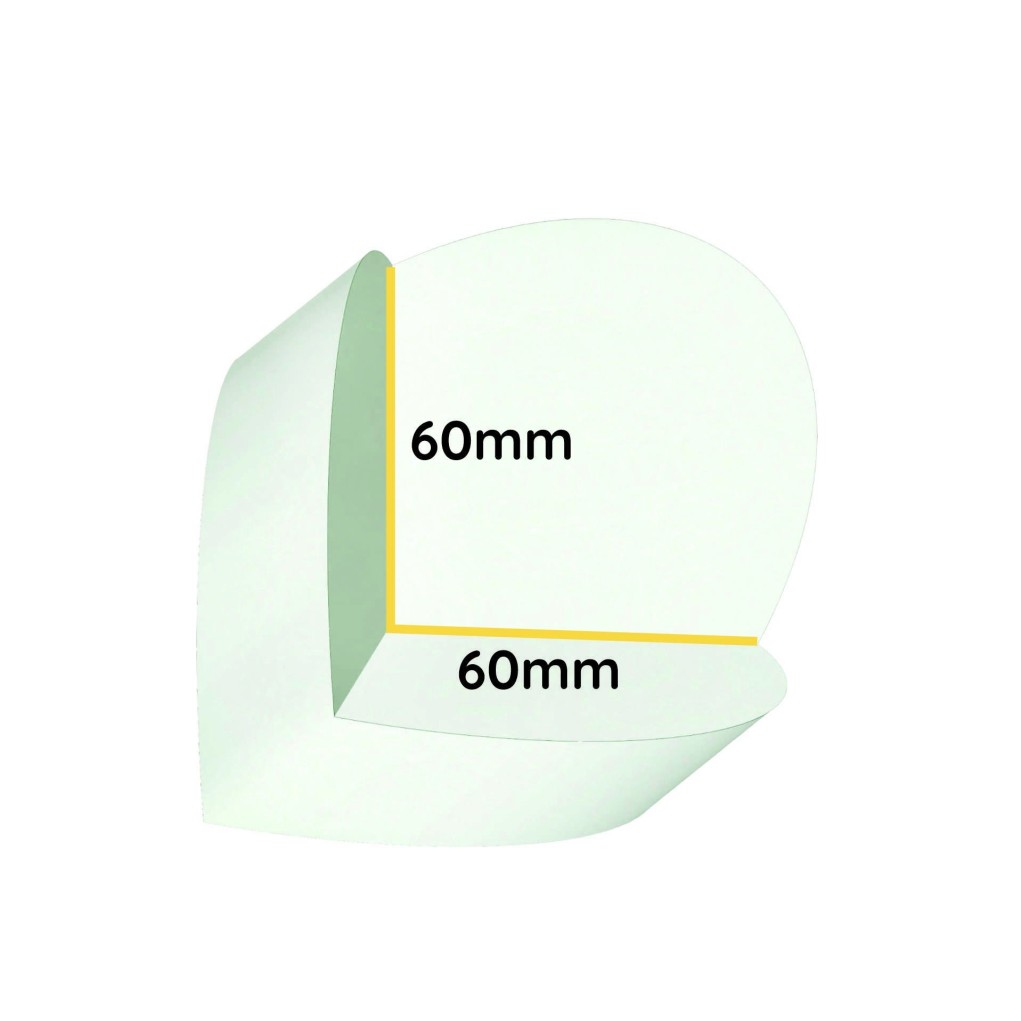

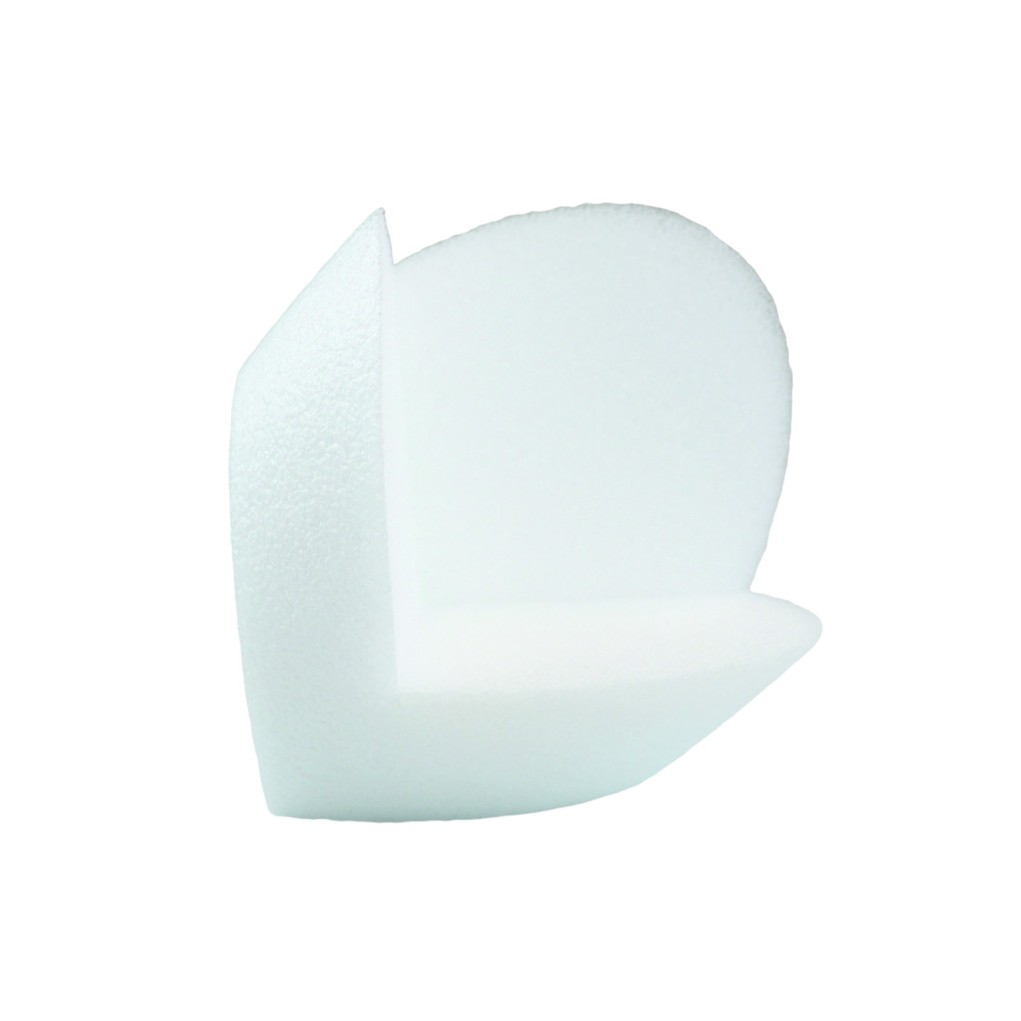

A whole 25 mm of foamed polyethylene in each wall creates the most powerful shock-absorbing barrier you can get straight off the shelf. The Cut-Corner 100/25 model covers corners up to 60 mm wide and pushes the goods away from the cardboard walls by as much as 25 mm – an "air cushion" is created, which absorbs even violent impacts. The external height of 90 mm increases the distance between stacked loads, and with a density of 23-30 kg/m3 a single corner weighs only about 10 g, so it does not raise freight costs. This is perfect protection for 85–98ʺ screens, XXL stone countertops, control cabinets, or delicate laboratory devices 🛡️.

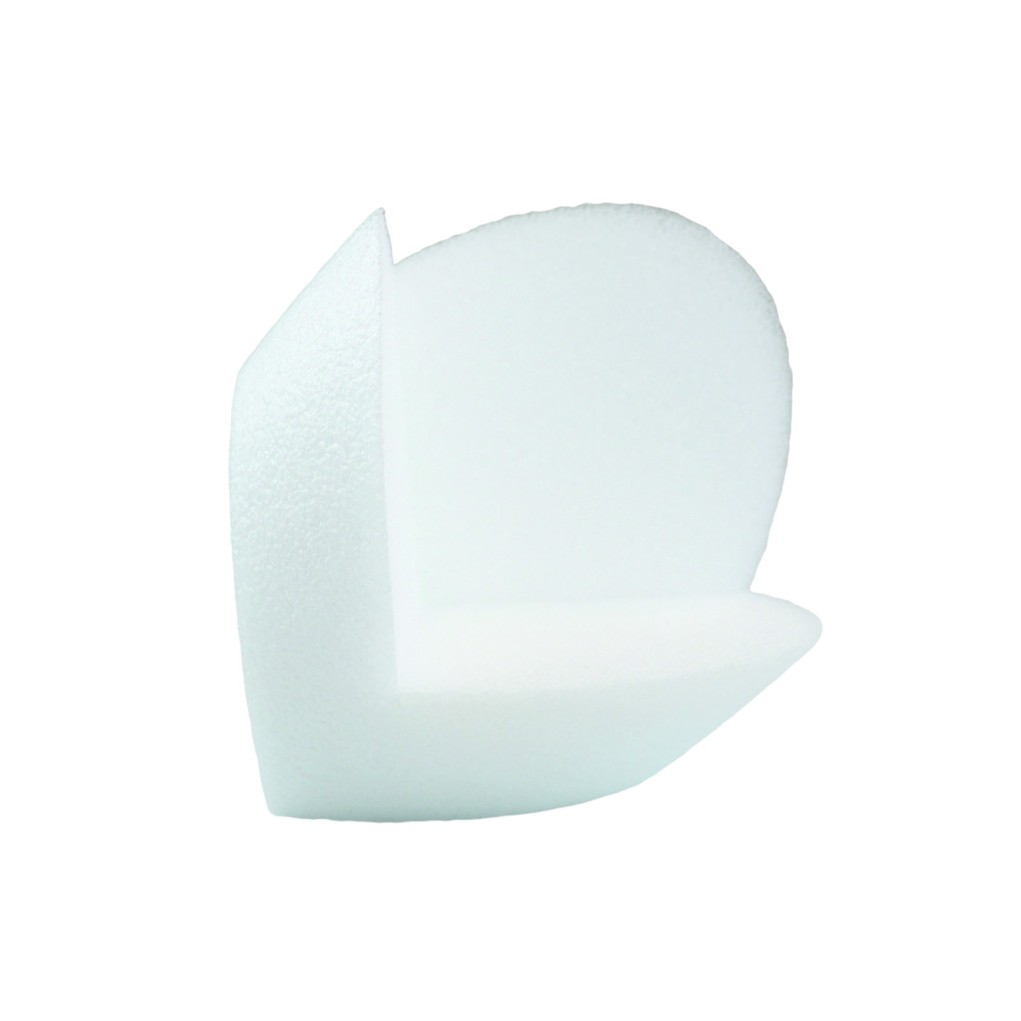

The Cut-Corner Corner is an "L" shaped foam profile that protects two adjacent surfaces of an object as well as the very tip of the corner. The 60 × 60 × 60 mm recess tightly encloses the edge, and the extremely thick 25 mm walls absorb the energy of impacts. The specially cut profile (cut) clamps the corner in place, so the cover does not slide off even with strong vibrations. The result - sensitive corners remain intact, and edge damage becomes a thing of the past.

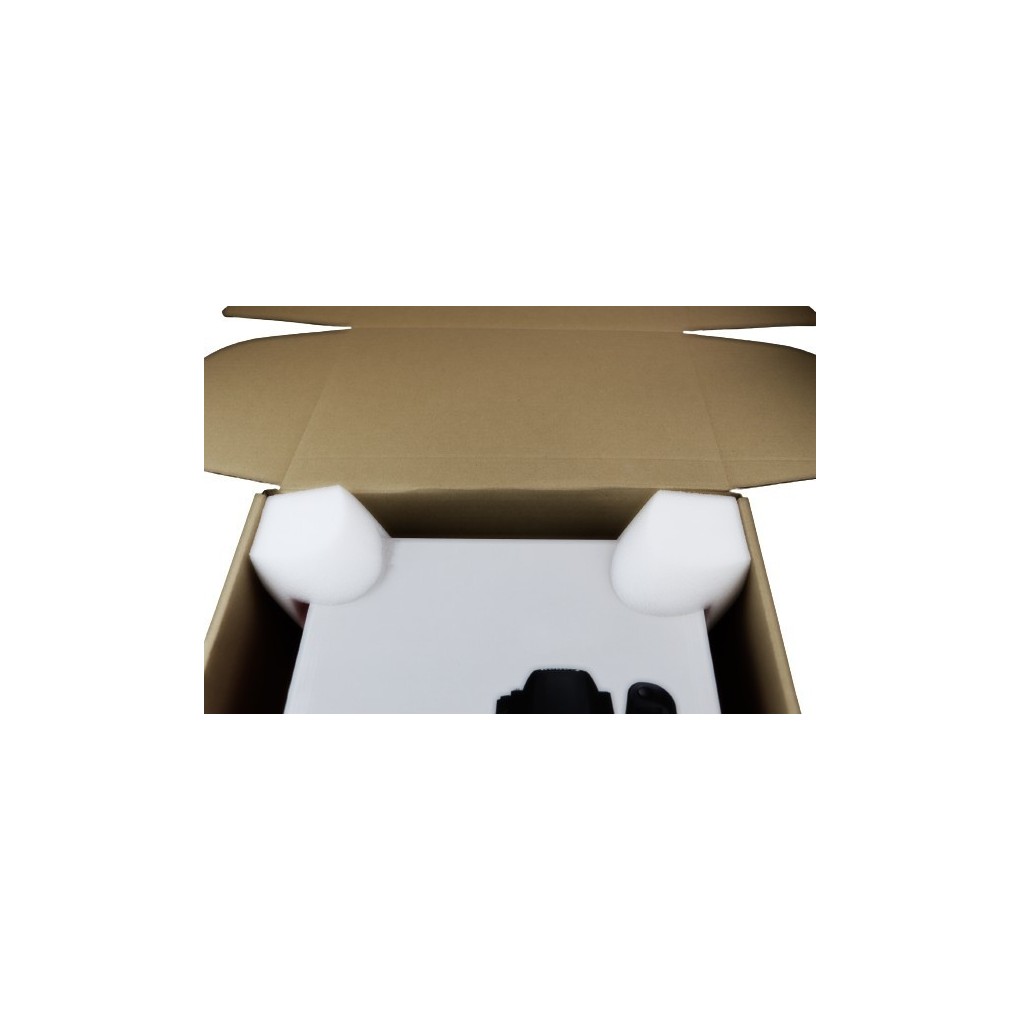

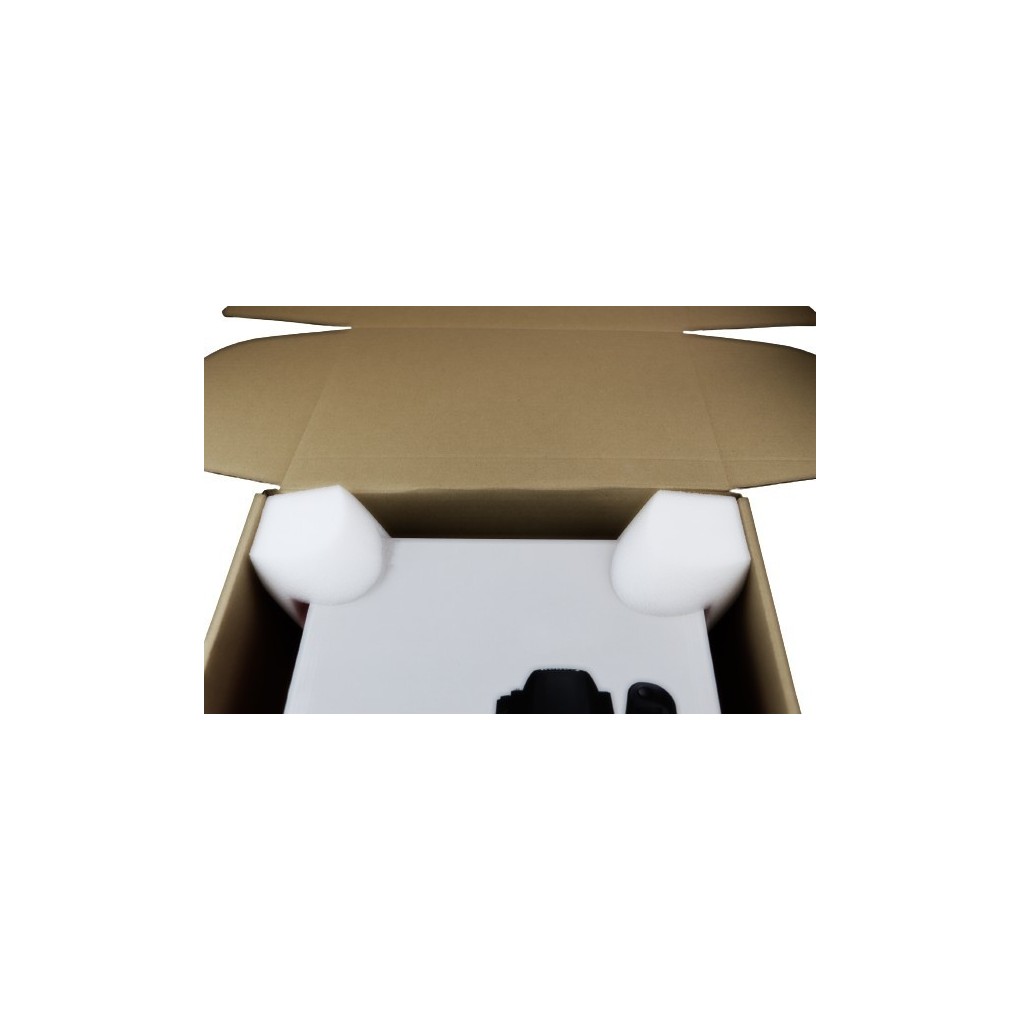

In logistics, foam corners are the simplest and at the same time incredibly effective way of damping. You put them on all corners (four or eight) and immediately create a distance from the cardboard wall. Shocks from the conveyor, forklift maneuvers or turbulence in the plane are no longer dangerous - your goods arrive in perfect condition 🎯.

The corners are made of foamed low density polyethylene (LDPE). Extrusion with the addition of gas creates a closed cell structure - millions of micro air cushions absorb the impact energy, while making the corner surprisingly light.

The LDPE granulate with a foaming gas is extruded into a continuous "L" profile 100 mm. The cooling tunnel stabilizes the cellular structure, after which the tape is cut into 100 mm sections. A CNC cutter forms a 60 mm recess with a tolerance of ± 0.5 mm. Each corner undergoes density and dimension control, is packed collectively, and goes for shipment 🚀.

Cut-Corner 100/25 was designed for multiple rotation. After use, it can be 100% ground into LDPE 4 regranulate. In energy recovery, PE does not emit toxic gases - minimal environmental footprint and full compliance with ESG policy.

Combine Cut-Corner corners with custom stitched cardboard - you'll get a mobile safe for your package:

Also available foam sheets 10 / 20 / 30 / 40 / 50 mm - we will select the optimal filler.

Launch the interactive creator , enter the dimensions, choose a thickness of 10-50 mm and color (white/black) - the quote will appear immediately.

Are you transporting oversized or exceptionally valuable goods? Contact us - we will prepare a favorable pallet offer for Cut-Corner 100/25 corners and help you choose the ideal PE foam parameters for your logistics.

from 1.79 € tax incl.

from 2.30 € tax incl.

from 1.37 € tax incl.

from 1.37 € tax incl.

from 18.86 € tax incl.

from 13.36 € tax incl.

from 0.63 € tax incl.

from 23.87 € tax incl.

from 13.36 € tax incl.

from 0.11 € tax incl.

from 21.48 € tax incl.

from 8.38 € tax incl.

from 1.23 € tax incl.

from 5.59 € tax incl.

from 8.38 € tax incl.

from 1.61 € tax incl.

from 0.67 € tax incl.

from 0.63 € tax incl.

from 2.44 € tax incl.

from 0.24 € tax incl.

from 17.23 € tax incl.

check_circle

check_circle

Please verify the country of delivery and form of purchase in the customer panel. The data provided in the customer panel differs from the currently set data.

Change settingsWe have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.