Brown flap cardboard K020 BC 600x400x400

from 11.57 zł tax incl.

| Quantity | Price tax incl./tax excl. |

|---|---|

| > 1 szt. | 1.60 zł 1.30 zł |

| > 480 szt. | 1.53 zł 1.24 zł |

| > 720 szt. | 1.48 zł 1.20 zł |

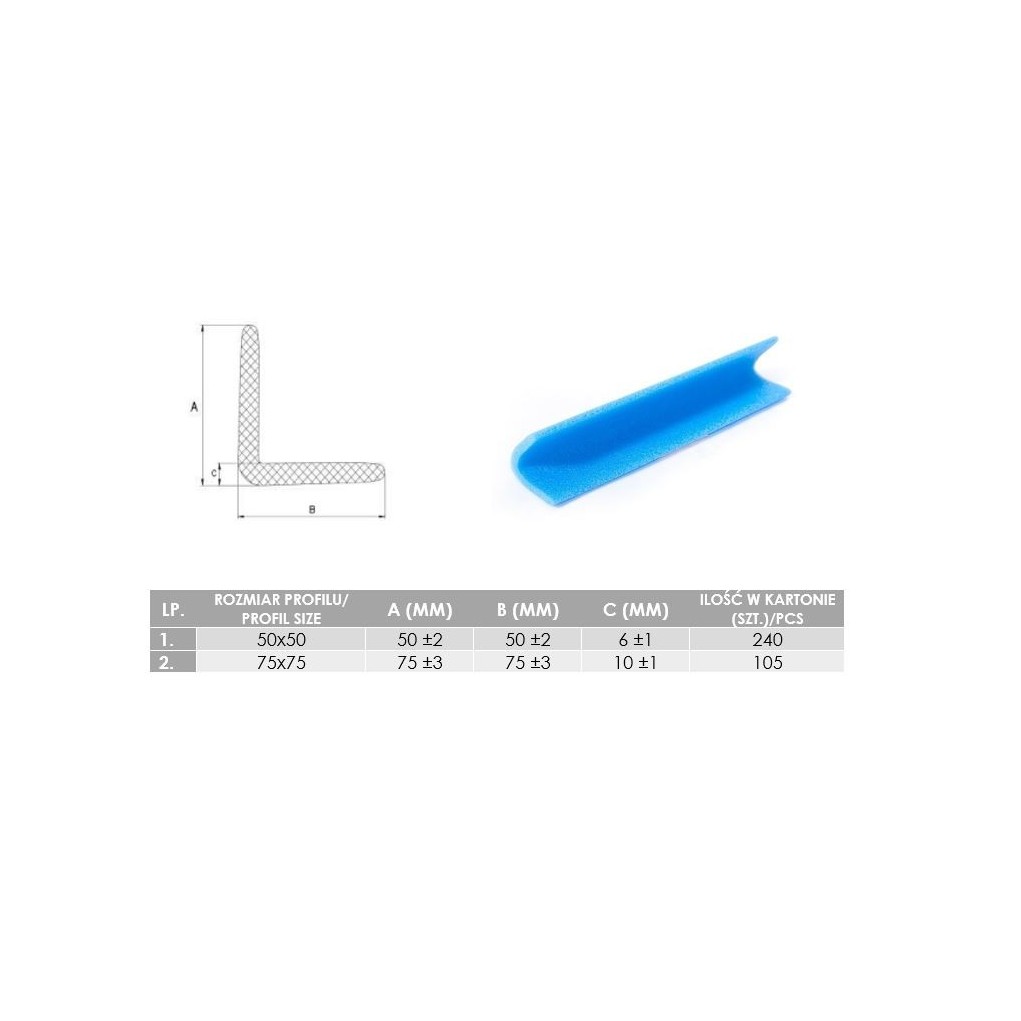

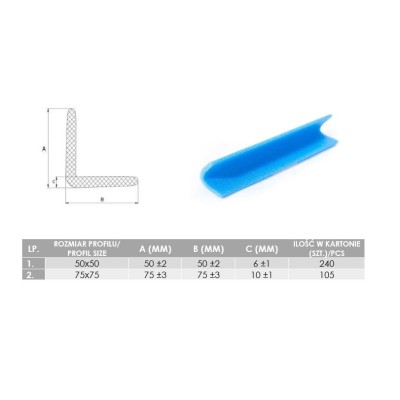

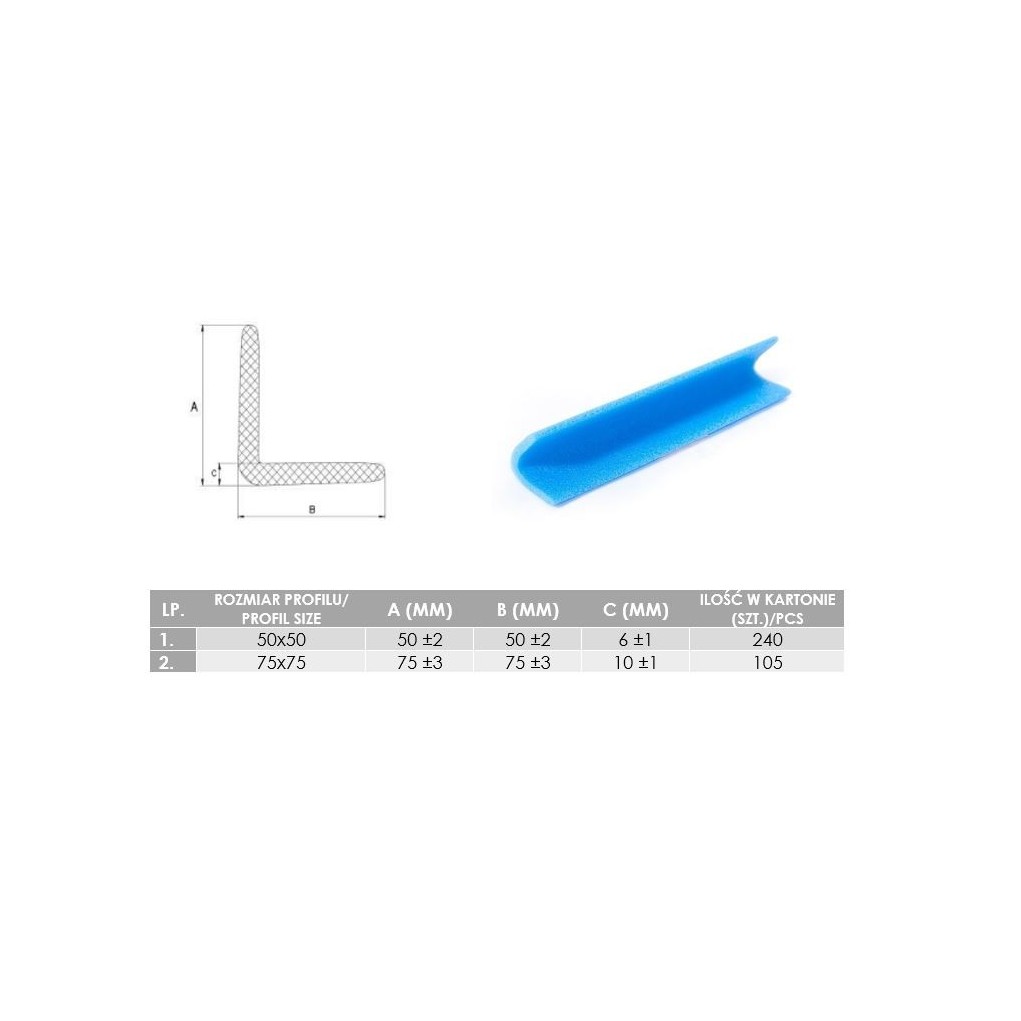

"L 50-50" is a universal foam profile in the shape of the letter L, protecting corners (internal and external) and edges of products during transport and storage. It safely shields the corners of elements, covering them with two 50 mm arms - e.g. 40 mm furniture tops, cabinet fronts, window frames or washing machine casings. A one-meter section weighs only ≈ 17 g, so it does not increase shipping costs. The closed-cell PE foam acts like a dense network of micro air cushions, absorbing shocks and preventing dents and scratches on surfaces. The characteristic blue color facilitates quality control from packing to unpacking at the customer's location.

The "L" shaped profile is created in the continuous extrusion process of foamed polyethylene (LDPE/EPE). The "L 50-50" covers the product corner with arms 50 mm long, performing three key functions:

The table below compares the LDPE foam profile and the solid cardboard corner:

| Aspect | Foam profile (LDPE) | Cardboard corner |

|---|---|---|

| Material / production | Foamed LDPE, continuous extrusion; petrochemical raw material. | Layered KRAFT paper (L profile); renewable raw material. |

| Protective properties | Soft cushioning, dampens vibrations; no structural load capacity. | Rigid corner protection, carries loads; less cushioning. |

| Weight / volume | ≈ 17 g/piece; arms 50 mm → larger package dimensions. | ≈ 200 g/piece; wall 3–5 mm → minimal volume increase. |

| Resistance to moisture / chemicals | Hydrophobic, chemically inert. | Hygroscopic; PE coating makes it partially waterproof. |

| Recycling / ecology | Recycling LDPE #4; no biodegradation. | Biodegradable or waste paper; low carbon footprint. |

| Load stacking | Does not carry weight – only cushioning. | Strengthens edges – allows pallet stacking. |

If you are looking for solid cardboard corners, check out our full offer ➜

| Feature | U Profile | L 50-50 Profile |

|---|---|---|

| Application | Protection of edges of a specified thickness (e.g. 20–40 mm, 80–100 mm). | Protection of corners and edges at a 90° angle (50 mm arms). |

| "Auto-grip" function | Yes – elastic arms tightly "clamp" onto the edge, usually without additional tape. | No – the profile fits more loosely; additional securing (stretch/tape) is recommended. |

| Typical products | Stone blocks, sintered slabs, facade glass. | Furniture, home appliances, wooden structures, electronics. |

| Distance between elements | Closed throat – strictly defined thickness. | 50 mm arms – create a corner buffer in both planes. |

The "L 50-50" profiles are made of foamed polyethylene LDPE/EPE - a material marked with the recycling code #4. This allows them to be directed to the standard recycling stream of LDPE foils and bags after the end of their use.

If your company is implementing a zero-waste strategy, profiles can be:

Effect: one kilogram of recovered LDPE allows to avoid the emission of approx. 1.8 kg CO₂-eq in comparison with primary production (source: Plastics Europe, 2024).

In addition to ready-made L foam profiles, order dedicated PE foam sheets and cardboard dividers to create a complete layer system:

In the creator foam sheets , enter the length, width, and thickness (10 – 50 mm) and choose a color - the quote will appear immediately. The sheets serve as:

The creator cardboard dividers allows you to choose the format, number of layers, and grammage. Applications:

Packing furniture, appliances, or stone plates? Contact the Boxmarket team – we will prepare an offer for L 50 – 50 profiles and match PE sheets and cardboard dividers to make your supply chain fast, safe, and economical.

from 11.57 zł tax incl.

from 11.81 zł tax incl.

from 7.06 zł tax incl.

from 7.06 zł tax incl.

from 110.69 zł tax incl.

from 4.96 zł tax incl.

from 52.88 zł tax incl.

from 23.63 zł tax incl.

from 49.82 zł tax incl.

from 8.20 zł tax incl.

from 38.86 zł tax incl.

from 174.35 zł tax incl.

from 110.70 zł tax incl.

from 28.78 zł tax incl.

from 982.77 zł tax incl.

from 3.01 zł tax incl.

from 68.87 zł tax incl.

from 2.41 zł tax incl.

from 257.01 zł tax incl.

from 5.10 zł tax incl.

check_circle

check_circle

Please verify the country of delivery and form of purchase in the customer panel. The data provided in the customer panel differs from the currently set data.

Change settingsWe have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.