Brown flap cardboard K020 BC 600x400x400

from 11.57 zł tax incl.

| Quantity | Price tax incl./tax excl. |

|---|---|

| > 1 szt. | 2.45 zł 1.99 zł |

| > 210 szt. | 2.32 zł 1.89 zł |

| > 315 szt. | 2.25 zł 1.83 zł |

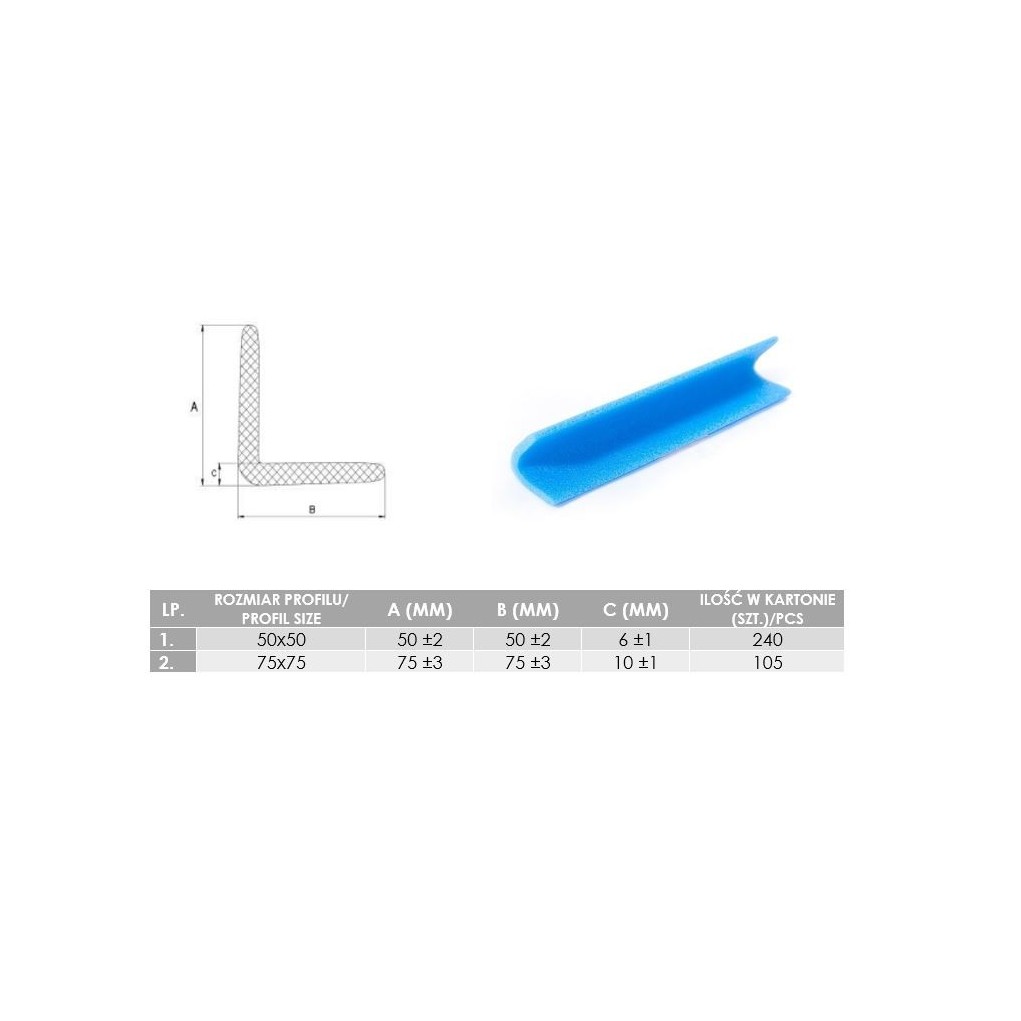

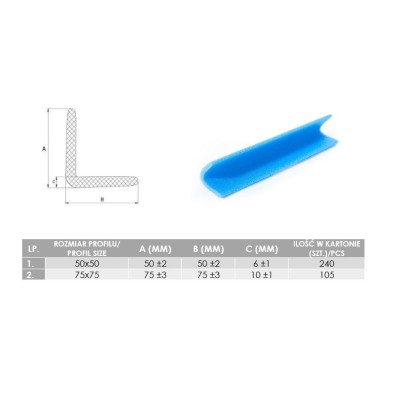

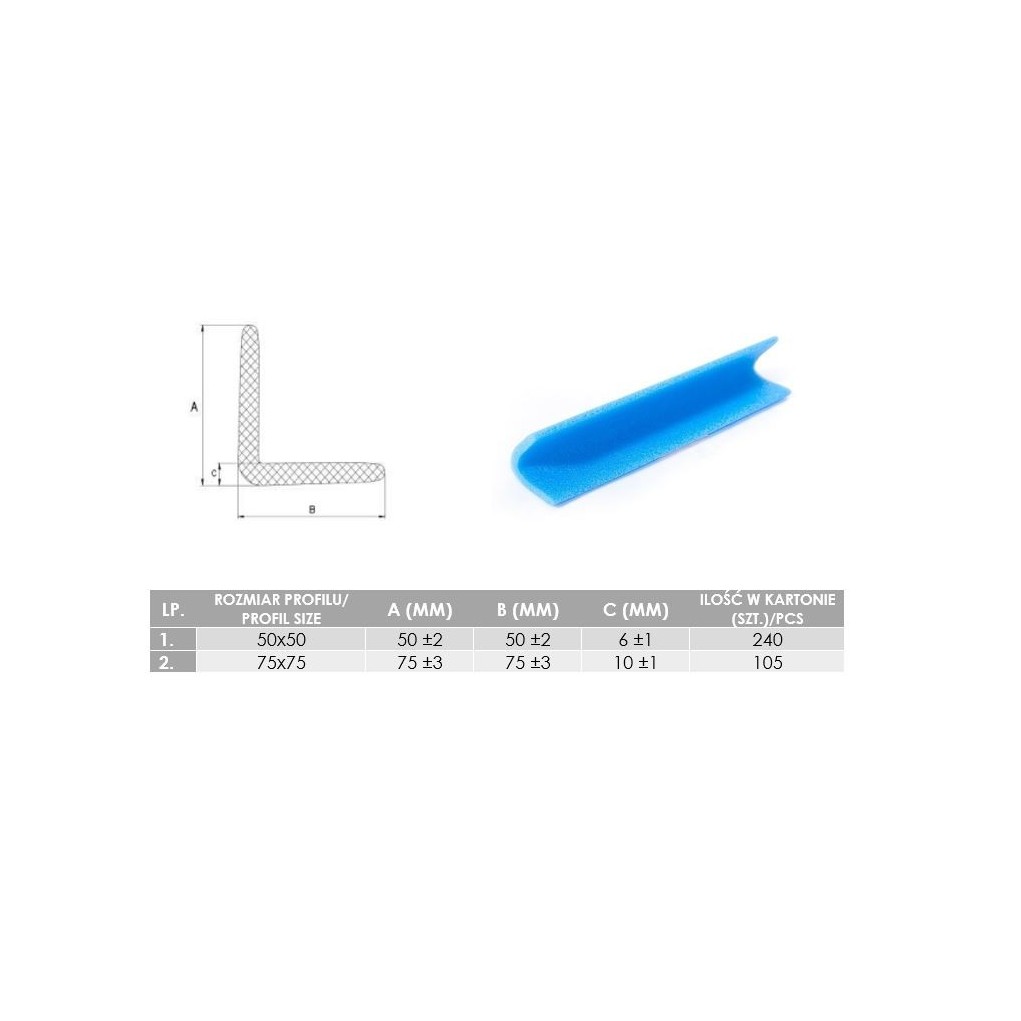

"L 75-75" is a reinforced foam profile in the shape of the letter L designed to protect massive corners and wide edges during transport and storage. Two 75 mm arms securely cover the corners of 60-70 mm stone blocks, facade windows, steel doors, side-by-side fridge housings and control cabinets. Despite its large format, a one-meter section weighs only ≈ 26 g, so it does not burden freight costs. Closed-cell PE foam creates a dense matrix of micro air cushions that absorb shocks and prevent chipping. The characteristic blue color makes it easy to quickly check whether every corner has been secured.

The "L 75-75" profile is created in the continuous extrusion process of foamed polyethylene LDPE/EPE. It covers the corner of the element with 75 mm arms, performing three key functions:

The table below compares the LDPE foam profile and the solid cardboard angle:

| Aspect | Foam profile (LDPE) | Cardboard angle |

|---|---|---|

| Material / production | Foamed LDPE, continuous extrusion. | Layered KRAFT paper (L profile). |

| Protective properties | Soft damping, vibration absorption. | Rigid shielding, carries loads. |

| Weight / volume | ≈ 26 g/piece; arms 75 mm. | ≈ 270 g/piece; wall 3-5 mm. |

| Resistance to moisture / chemicals | Hydrophobic, chemically neutral. | Hygroscopic; optional PE coating. |

| Recycling / ecology | LDPE #4; no biodegradation. | Biodegradable or waste paper. |

| Stacking load | Does not carry weight – damping. | Strengthens edges – pallet stacking. |

Need solid cardboard corners? Check out our full offer ➜

| Feature | U Profile | L 75-75 Profile |

|---|---|---|

| Application | Protection of edges of a specified thickness. | Protection of corners and 90° edges (75 mm arms). |

| "Auto-grip" function | Yes – strong clamp without tape. | No – additional securing is recommended. |

| Typical products | Stone blocks, facade glazing. | Furniture, home appliances, steel constructions. |

| Gap between elements | Tightly with the throat – constant thickness. | Corner buffer in both planes. |

The "L 75-75" profiles are made of LDPE/EPE (recycling code #4), so after use they can be given to the standard LDPE film stream.

Effect: 1 kg of recovered LDPE saves ~1.8 kg of CO₂-eq compared to primary production (Plastics Europe, 2024).

In addition to ready-made L 75-75 profiles, order PE foam sheets and cardboard dividers to build a complete layer system:

Creator foam sheets – enter dimensions (10 – 50 mm) and color; you will receive an immediate quote.

Creator cardboard dividers – choose the format, number of layers and grammage.

Packing massive countertops, Jumbo glass or large appliances? Contact the Boxmarket team – we will prepare an offer for L 75-75 profiles and adjust PE sheets and cardboard dividers so that your supply chain is fast, safe and economical.

from 11.57 zł tax incl.

from 9.84 zł tax incl.

from 7.06 zł tax incl.

from 7.06 zł tax incl.

from 174.35 zł tax incl.

from 38.86 zł tax incl.

from 19.67 zł tax incl.

from 3.68 zł tax incl.

from 11.29 zł tax incl.

from 38.86 zł tax incl.

from 0.48 zł tax incl.

from 11.29 zł tax incl.

from 23.63 zł tax incl.

from 15.89 zł tax incl.

from 2.09 zł tax incl.

from 9.53 zł tax incl.

from 174.35 zł tax incl.

from 1.60 zł tax incl.

from 7.06 zł tax incl.

from 47.33 zł tax incl.

check_circle

check_circle

Please verify the country of delivery and form of purchase in the customer panel. The data provided in the customer panel differs from the currently set data.

Change settingsWe have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.