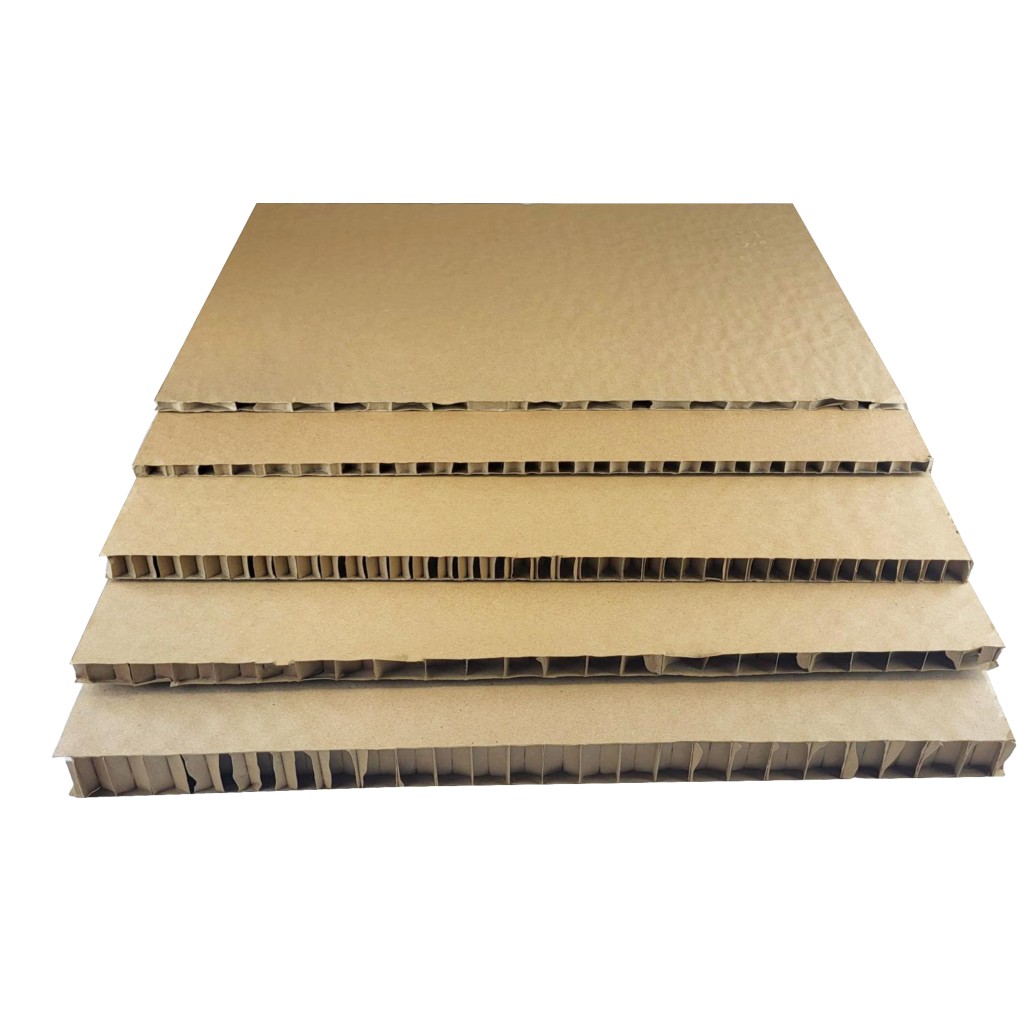

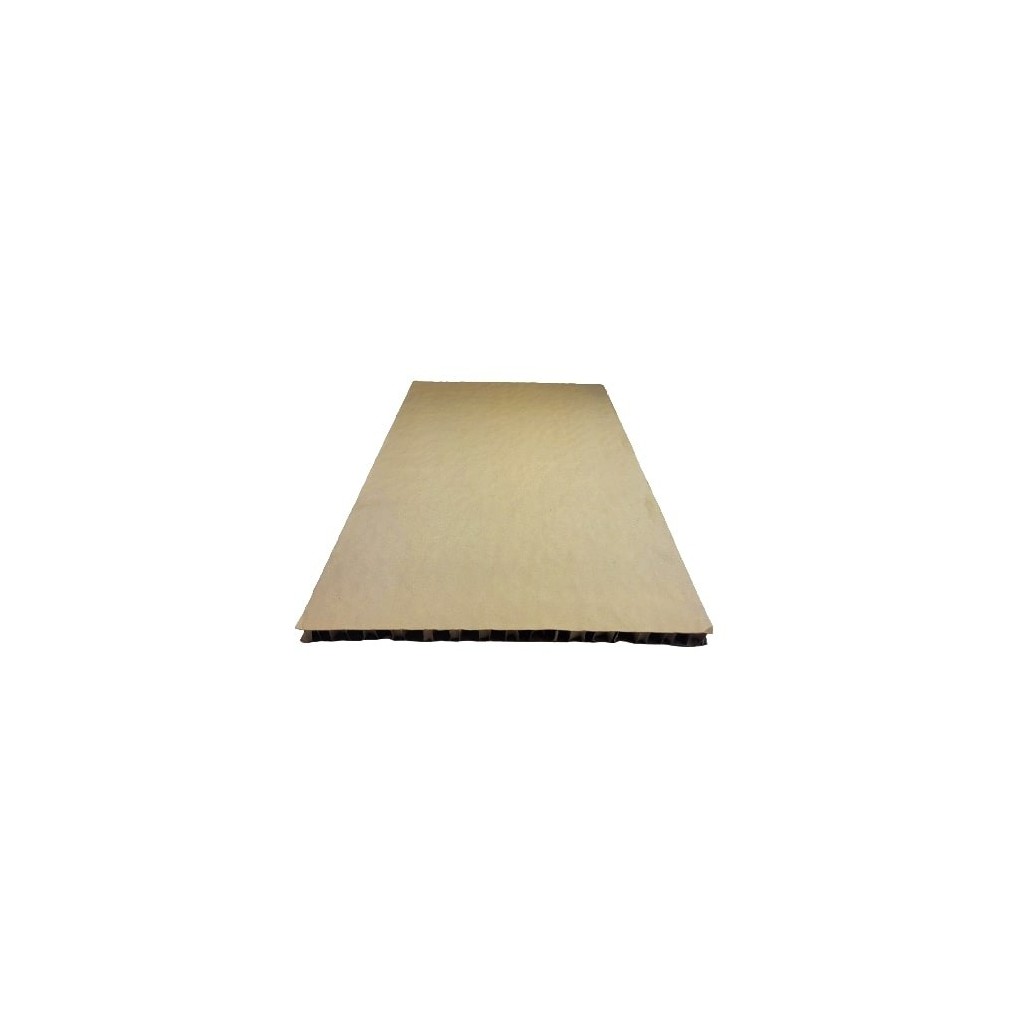

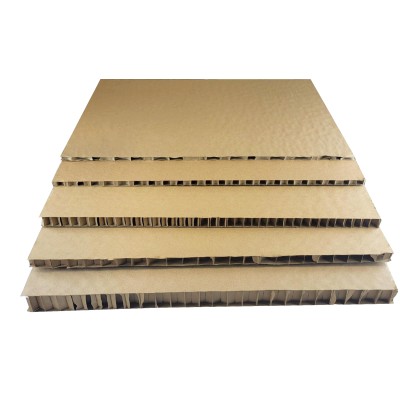

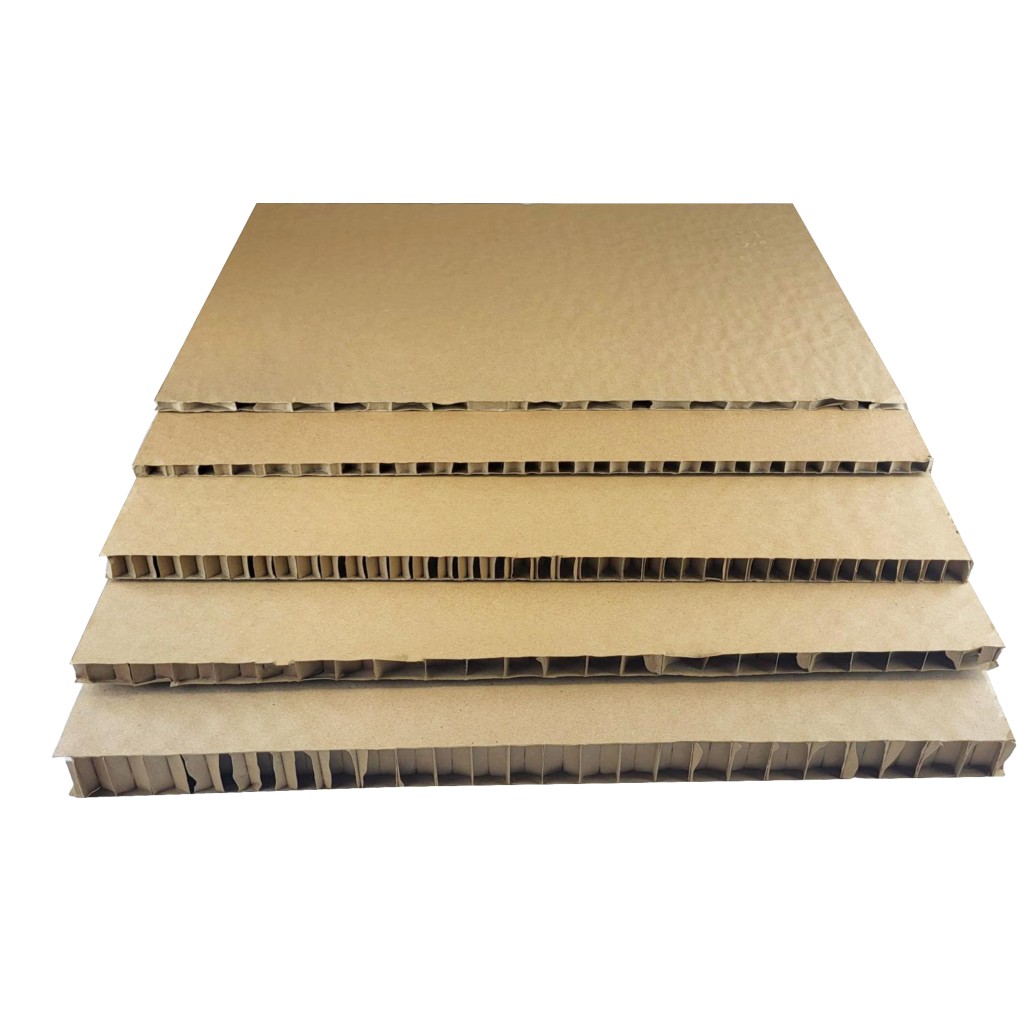

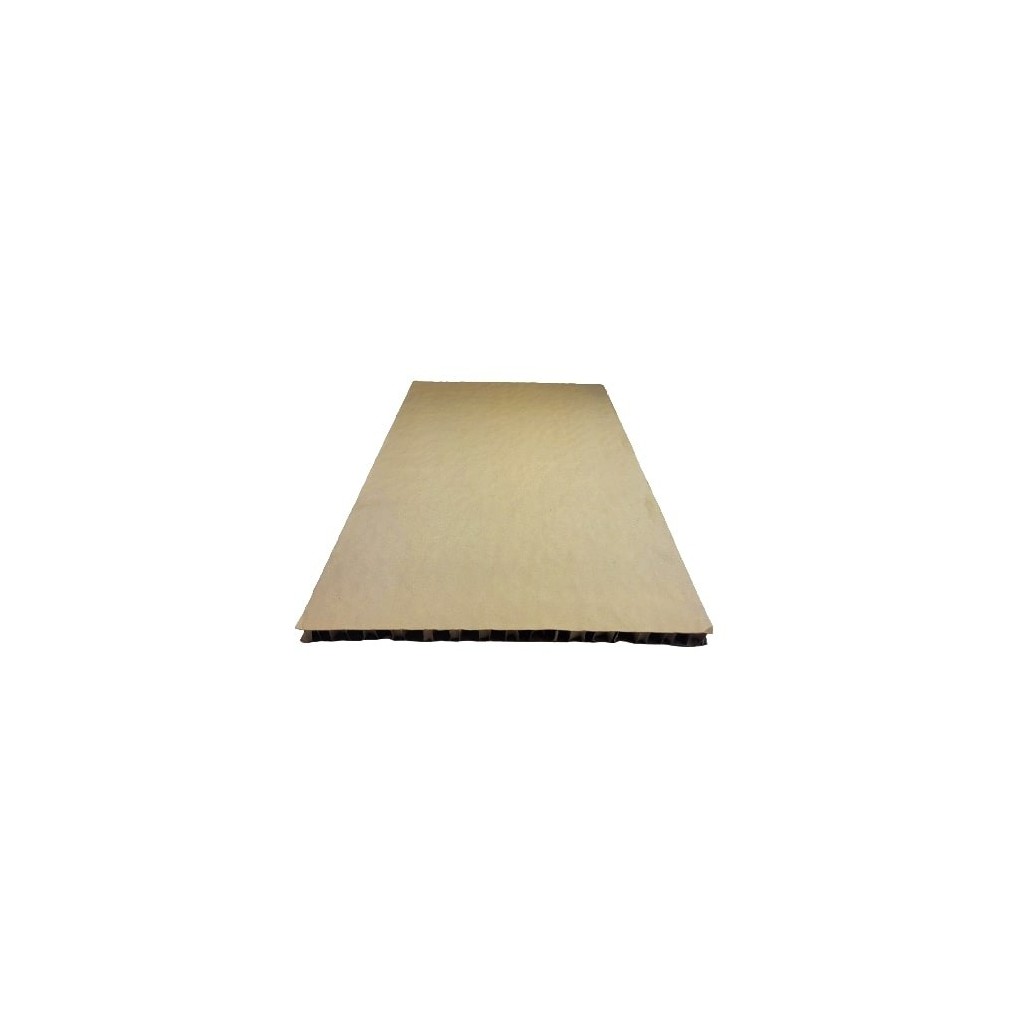

"Honeycomb" Cardboard Sheet 600 × 400 × 40 mm - Extreme Thickness, Extreme Protection

"Honeycomb" paper structure - a forty-millimeter core of hexagonal cells + durable testliner faces - creates an extremely rigid, yet surprisingly light plate resistant to crushing, point impacts, and vibrations. Despite its impressive height, the sheet is over eleven times lighter than a 40 mm wooden plate, and after use, it goes directly into the waste paper stream. The format 600 × 400 × 40 mm will work as a spacer, a distance insert, and a cushioning "nest" in the transport of heavy-duty loads.

🍯 What exactly is a "honeycomb" structured sheet?

Honeycomb sheet is created in three steps:

- Core expansion – strips of kraft paper are glued with starch glue into a block, then "stretched" to create a rigid network of hexagons with a height of 40 mm.

- Laminating the covers – both sides are reinforced with testliner (recycled paper), which carries tensile and compressive stresses like the straps of a double-T beam.

- Cutting to size – the finished plate is laser or tape cut to a size of 600 × 400 mm; tolerance ± 1 mm.

- 🔬 Base material: 100% kraft paper + water-based starch glue.

- 🪶 Surface weight (40 mm): approx. 1.80 kg/m² – still lighter than PE foam 30 kg/m³.

- 📊 Core parameters: height 40 mm · mesh 15 mm · wall 0.2 mm.

- 🌍 Ecology: 100% biodegradable, compostable and recyclable in the waste paper stream.

🧪 Key properties – stiffness + damping

Combines the load-bearing capacity of a wooden beam with the flexibility of foam, protecting the load both during warehouse compression and during violent shocks in transport.

- 🏋️♂️ Reliable protection when stacking – withstands pressure up to 2,000 kg / m², so pallets won't flatten even on the lowest layer.

- 📏 Less distortion – stiffness 95% higher than in PE foam minimizes claims caused by crushing.

- 💥 Absorbs shocks – 40 mm core absorbs the energy of a fall from 1.5 m, protecting glass, marble and precision electronics.

- 🔄 Multiple use – recovers ≈85% of height in 30 s, suitable for several transport cycles.

- 🪶 Significant weight reduction – 1.80 kg/m² vs. pine board 40 mm ≈ 20 kg/m²; cheaper freight and lower CO₂ footprint.

One sheet replaces thick wooden plates + PE foam, simplifying packaging and reducing logistics costs.

- 🌡️ From frost to heat – stable parameters from -20 °C to +70 °C.

- 🌧️ Not afraid of moisture – short-term dampness does not reduce stiffness; the product is not intended for constant exposure to water.

- ⚡ Electronics-friendly – antistatic version discharges charges, protecting sensitive components.

- 🍏 Food contact (indirect) – paper and starch glue do not transfer flavors or odors; no certificate for direct contact.

- 🔥 Easy disposal – combustion < 1% ash, high energy recovery.

📦 Typical applications – how you can benefit

- 📑 Heavy-duty pads – stabilize layers of castings, engines and traction batteries.

- 🔄 3D Spacers - you crease wedges and frames blocking loads of 500 kg+.

- 🫧 Protection of XXL stone & glass – marble, granite, 10 mm panes on long routes.

- 🛡️ 40 mm angles – protect stone countertops and premium furniture.

- 📦 Eco-insert for heavy e-commerce – aquariums, hi-fi amplifiers, microscopes.

- 🏗️ XL POS structures – 3 m walls assembled without tools, 30% cheaper freight.

- 🪑 Ultralight furniture – door filling 50 mm, mass reduction by 40%.

🏭 Industries already using 40 mm thickness

- 💻 Electronics & optics – 85″ screen separators, server chassis.

- 🚗 Automotive & aerospace – engine spacers, battery packs, composite panels.

- 🪨 Stonemasonry & premium countertops – granite and quartz sinter transport.

- 🍾 Food & premium beverages – nests for 12 l barrels and 10 kg jars.

- 🥼 Medical equipment – tomographs, tabletop autoclaves.

- 🎨 Large-format POS systems – reusable stage modules.

⚖️ Comparison with PE foam

| Criterion |

"Honey Plaster" 40 mm |

PE Foam 40 mm |

| Composition |

100% paper + water glue |

LDPE Polyethylene |

| Surface mass |

≈ 1.80 kg/m² |

≈ 2.8 kg/m² |

| Load-bearing capacity / stiffness |

Up to 2,000 kg/m² |

Low stiffness |

| Recycling / disposal |

Blue container ♻️ |

LDPE 4 Collection |

| Biodegradability |

Yes |

No |

| Carbon footprint |

Low |

High |

If you are looking for PE foam sheets, check out our

full offer ➜

⚙️ Technical specification

- Material: paper (testliner + kraft)

- Format: 600 mm × 400 mm × 40 mm

- EAN: 5905489972259

♻️ Recycling and reuse – we close the loop

Honeycomb sheet is 100% homogenous paper, so "cleaning up" after it is as simple as throwing out a newspaper.

- 🗑️ Recycling without guessing – you throw it into the blue container along with cardboard and newspapers.

- ♻️ Full cycle closure – the paper mill processes it into new cardboard within a few days.

- 🔄 Second life in the warehouse – after regaining thickness, it serves as a separator for the next cycles.

- 🌱 Composting option – In a BIO facility, it breaks down into humus within a few weeks.

- 🔥 Energy without toxins – burning generates < 1% ash, high heat recovery.

📦 Custom size cartons and packaging personalization

Combine a cardboard cut to the millimeter with a 40 mm sheet to build an all-paper packaging: no plastic, one recycling fraction, maximum protection.

- 🔒 Zero clearance – the format + box eliminates empty spaces.

- 🌍 Zero plastic – the customer throws everything into the wastepaper.

- 💡 A brand that makes an impression – inside/outside printing, eco-look.

- 📦 Less volume = lower costs – compact packages, cheaper freight.

- ♻️ One waste fraction – simpler segregation at the recipient's.

Take advantage of

Custom size cartons

or add a logo thanks to

Printed cartons

.

📞 Bulk orders and advice

Contact us - we will set the eyelet 8-25 mm, grammage lic 150-350 g/m², hydrophobic coating or ESD and prepare an offer for your volume.

Trivia:

- 🧊 Hydrophobic + self-extinguishing - the variant meets B-s1,d0 and repels water (Cobb 60 ≤ 25 g/m²).

- 📊 80% air - the empty hexagonal core guarantees the best weight to load ratio.

- 🔧 Parameters on request - eyelet 8-25 mm, faces 150-350 g/m², thickness 10-50 mm; load capacity up to 2,200 kg/m².