Ecological benefits of flap boxes – recycling and sustainable solutions

Contents:

- The Production Process of Flap Boxes – From Raw Material to Finished Product

- Key Points

- Eco-Friendly Flap Boxes – Addressing Environmental Challenges

- Ecological Responsibility in Practice

- Eco-Friendly Production of Flap Boxes

- The Wet Method – Tradition and Challenges

- The Dry Method – A Sustainable Choice

- Certificates and Labels – Responsibility in Every Detail

- Recycling and Reusing Materials

- Sustainable Development – The Future of Flap Boxes

- Summary

- FAQs – Frequently Asked Questions

The Production Process of Flap Boxes – From Raw Material to Finished Product

In addition to practical advantages, such as ease of transportation and storage, flap boxes stand out for their environmental benefits. They are biodegradable, easy to recycle, and can be made from recycled materials, making them an eco-friendly alternative to other types of packaging. This article will examine how flap boxes support sustainable development and help reduce the negative impact on our planet.

Key Points

- Flap boxes are biodegradable, recyclable, and can be produced from recovered materials.

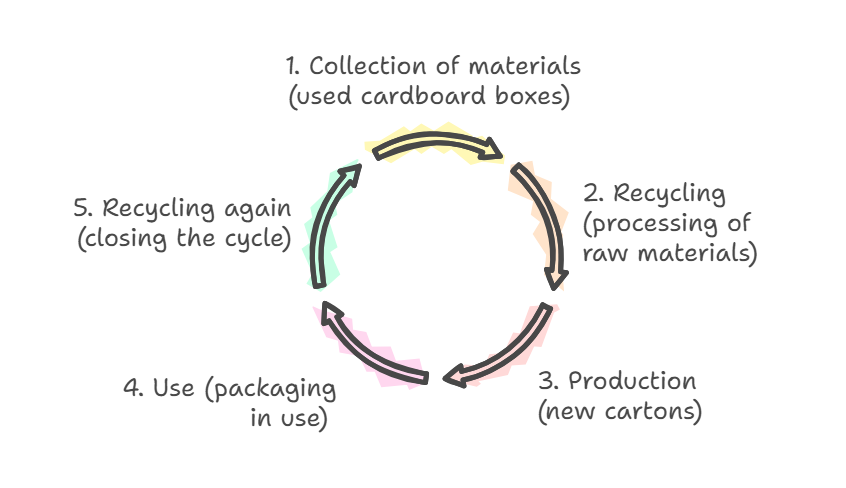

- The use of flap boxes promotes a circular economy and reduces the carbon footprint.

- Flap box production requires lower energy input, saving natural resources in the process.

Eco-Friendly Flap Boxes – Addressing Environmental Challenges

Year after year, businesses are under increasing pressure to minimize their negative environmental impact. Key challenges such as reducing waste and greenhouse gas emissions stem not only from regulatory requirements but also from consumer expectations and market trends. In response, more and more companies are opting for eco-friendly flap boxes . Their biodegradability and recyclability support a circular economy while also reducing the consumption of raw materials and CO₂ emissions.

However, flap boxes aren’t limited to a single industry sector. Flap packaging fits perfectly in sectors such as e-commerce, food, pharmaceuticals, industry, and even apparel . Each finds in these boxes a solution tailored to its needs—whether for safe shipping, product storage, or protection against damage. Moreover, some sectors, particularly the food and pharmaceutical industries, are further compelled by legal regulations to use environmentally friendly packaging, driving continued development of green solutions.

Social pressure and the expectations of individual customers also play a crucial role in the choice of eco-friendly packaging. An ever-increasing number of consumers pay attention to how products are packaged, and companies that fail to meet these expectations risk losing their competitive edge.

Thanks to their universality and eco-friendliness, flap boxes have become a cornerstone of many companies’ sustainability strategies, meeting the demands of both the market and the environment.

Ecological Responsibility in Practice

Companies that opt for eco-friendly flap boxes enjoy many benefits:

- Less plastic: Boxes replace harder-to-recycle plastic, helping reduce waste.

- Lower CO₂ emissions: Using recycled materials cuts carbon dioxide output during production.

- Support for a circular economy: The repeated reprocessing of cartons lowers the demand for new raw materials, aiding the conservation of natural resources.

Individual customers can likewise join these efforts by choosing products packaged in eco-friendly boxes. Such choices support sustainable development and help protect the environment.

Eco-Friendly Production of Flap Boxes

The production of flap boxes plays a vital role in the transition to more sustainable solutions within the packaging industry. Choosing the right manufacturing methods can significantly impact the reduction of natural resource consumption, greenhouse gas emissions, and waste generation.

The two main methods—wet and dry—differ in their environmental impact and resource-use efficiency. Understanding their advantages and limitations makes it easier to determine how to minimize the ecological footprint of flap-box manufacturing while promoting a circular economy. Below, both methods are discussed in terms of their applications and characteristics.

The Wet Method – Tradition and Challenges

Wet-method box production relies on cellulose fibers mixed with water to create pulp. After the sheets of carton are formed, the water is evaporated, which requires intensive drying.

While the wet method is effective in producing high-quality cartons, its main drawbacks include:

- High water consumption—particularly important in regions with water scarcity.

- Energy-intensive drying process.

- Potential environmental contamination from industrial wastewater.

The Dry Method – A Sustainable Choice

The dry method, based on using waste paper, is significantly more eco-friendly. This process uses minimal water and energy, and repurposing paper waste reduces landfill accumulation. Key benefits of the dry method include:

- Reduced CO₂ emissions during production.

- The ability to use local raw materials, which cuts transport costs and carbon footprint.

- Minimal production waste thanks to reusing leftover materials.

When it comes to flap-box production, the dry method is most commonly used. It’s environmentally friendly, cost-effective, and consistent with sustainable-development principles. Employing recovered paper reduces the harvesting of virgin natural resources and lowers waste volume, aligning perfectly with the needs of modern, eco-friendly packaging solutions.

Certificates and Labels – Responsibility in Every Detail

Today, boxes and cartons on the market often bear various certifications—both local and international. One of the most significant is the FSC® (Forest Stewardship Council) certificate, ensuring that the material used for packaging originates from responsibly managed forests.

This allows consumers to trust that the product supports sustainable forestry, safeguarding nature and promoting environmental initiatives. The FSC® certificate is crucial in the paper, furniture, and packaging industries.

At Boxmarket, we champion eco-friendly packaging production by offering products made from environmentally conscious materials. We continually strive to reduce our carbon footprint while following sustainable development principles, aligning with our core mission to create both functional and eco-friendly solutions for businesses and consumers alike.

Recycling and Reusing Materials

Sustainable Development – The Future of Flap Boxes

Sustainability in the context of flap boxes goes beyond just using environmentally friendly materials. It also involves pursuing innovations in the production and distribution of these packages. We can expect further advancements in technology enabling flap boxes with an even smaller carbon footprint in the future. Such changes may include the use of new, biodegradable materials that are fully compostable or easier to recycle. With developments in production methods and logistical processes—such as optimizing energy use and minimizing waste—flap boxes will become an even more sustainable alternative compared to other packaging materials.

It should be stressed that the future of flap boxes also relates to increasing awareness among consumers and businesses. Brands that adopt pro-ecological decisions gain a competitive market advantage by meeting the expectations of environmentally conscious customers. Moreover, changes to environmental regulations and the growing number of eco-responsibility mandates on companies will drive further expansion of sustainable packaging solutions. Accordingly, the sustainability of flap boxes is not only an answer to current ecological demands but also a foundation for the future of the packaging sector.

Myth Busting: Eco-Friendly Flap Boxes Are Not Less Durable. Research shows that with technological progress, the quality of paper fibers obtained from recycling can be equivalent to virgin raw materials, provided suitable reprocessing methods and reinforcing additives are used to strengthen the box’s structure.

Summary

In conclusion, flap boxes provide an excellent example of packaging that merges functionality with ecological accountability. Thanks to their biodegradability, recyclability, and the use of recovered materials, they form a key part of many companies’ sustainable-development strategies. Their contribution to supporting the circular economy and curbing environmental damage is invaluable, especially under growing pressure to cut waste and greenhouse gas emissions.

“Fig. A closed-loop cycle in producing eco-friendly flap boxes

FAQs – Frequently Asked Questions

1. What’s the difference between flap boxes made from recycled materials and those from virgin raw materials?

Recycled cardboard is just as durable as virgin cardboard, but it exerts a smaller impact on the environment. Using recycled content helps conserve natural resources and lower CO₂ emissions, thus supporting sustainable development.

2. Are flap boxes made in an eco-friendly manner more expensive than traditional packaging?

Eco-friendly cartons may have a higher upfront price, but through reduced costs linked to waste and resource usage, they yield long-term savings. Moreover, choosing them can boost a brand’s image among environmentally conscious consumers.

3. What certifications do eco-friendly flap boxes hold?

Eco-friendly flap boxes often bear certifications such as FSC® and PEFC, confirming that their raw materials come from responsibly managed sources. They may also comply with quality standards related to recycling and sustainability, ensuring their environmental friendliness.