Best storage practices for flap cartons - how to store optimally?

Contents:

- Key Points

- Keeping Cartons Under Control – How to Store Cardboard Packaging so It Lasts Longer?

- Warehouse Organization = Better Packaging

- Stacking Tips – Ensuring Safety and Longevity

- Protecting Against Pests – Warehouses Full of Uninvited Guests

- Proper Labeling and Documentation – Key to Efficient Logistics

- Staff Training – Foundation for Effective Storage and Carton Protection

- Summary

- FAQs, or Frequently Asked Questions

The durability and functionality of flap boxes does not start the moment they’re used, but rather where they’re stored. Properly stored cardboard packaging can serve reliably for a long time, whereas unfavorable conditions can quickly turn it into worthless waste. How can you care for boxes so that they retain their quality and perform their function? Discover proven storage methods that will help you avoid losses and optimize your workflow.

Key Points

- Storing flap boxes requires maintaining optimal temperature and humidity levels to prevent the material from deforming.

- Keeping boxes on pallets, following the FIFO principle, and avoiding exposure to water are key principles for organizing warehouse space.

- Proper labeling of boxes speeds up inventory management and reduces the risk of errors.

Keeping Cartons Under Control – How to Store Cardboard Packaging so It Lasts Longer?

Every product has specific storage requirements—some need a cooler environment, while others fare better in warmer temperatures. What about flap boxes? Although they’re simple in design and versatile, cardboard packaging must be properly cared for to maintain its properties. According to manufacturers, the optimal temperature for storing flap boxes ranges from 15°C to 25°C with standard humidity. Proper storage not only extends their lifespan but also prevents issues like warping or moisture absorption.

The cardboard used to make flap boxes absorbs moisture, which can cause it to soften and lose its structural integrity. To keep this from happening, pay attention to these key aspects:

- Temperature: The warehouse should maintain a consistent temperature. Extreme temperature fluctuations can weaken the box’s structure.

- Humidity: The recommended relative humidity should be in the 40–60% range. Excessive moisture causes the cardboard to swell, while overly dry air leads to brittleness.

- Ventilation: The warehouse must be well-ventilated to prevent mold growth and minimize the risk of dampening the packaging.

Warehouse Organization = Better Packaging

When purchasing flap boxes , think ahead about their “future”—meaning how they’ll be stored. Securing them just after purchase isn’t enough. Simply “tossing” boxes into a basement or garage can lead to irreversible damage that affects packaging quality. Proper storage and organization from the moment you have them is key to their longevity and maintaining them in pristine condition.

Effective space management in the warehouse not only increases efficiency but also reduces the risk of box damage. Keep these guidelines in mind:

- Pallets and Shelves – Store boxes on pallets or shelving so they don’t come into direct contact with the floor, protecting them from moisture and mechanical damage.

- FIFO Principle – Arrange your warehouse to allow “first in, first out” usage. This prevents boxes from sitting in one place too long and potentially getting damaged.

- Avoid Water – Besides avoiding storage in basements, keep boxes away from places exposed to water, such as near water pipes or roofs prone to leaking.

- Storing Boxes Flat – New flap boxes are best stored flat, which offers several advantages, including:

- Saving space

- Protecting them from damage

- Retaining their shape

- Easier prep for future use

Stacking Tips – Ensuring Safety and Longevity

Properly stacking boxes is not only a matter of tidiness, but also safety and durability. Excessive loads, disorganized space, or poor stacking techniques can lead to damage, affecting box quality. Here are a few rules to help maintain stability and keep your flap boxes in good condition:

- Maximum Load – Don’t exceed the maximum load capacity of the lower layers. Overloading can cause deformation, undermining the stability of the entire stack.

- Heavier at the Bottom – Place heavier packages in the lower layers, and lighter ones up top.

- Avoid Shifting – Move boxes gently to avoid damaging edges or corners, which are especially prone to breaking.

Protecting Against Pests – Warehouses Full of Uninvited Guests

Warehouses often house not only flap boxes but also unwelcome visitors—pests such as rodents or insects. Dark corners and damp areas easily harbor these destructive guests, which can irreversibly damage both the packaging and its contents.

Though flap boxes can protect stored products, they need to be safeguarded from threats that may harm them. Implementing a few proven pest control measures will help keep your inventory safe.

Proper Labeling and Documentation – Key to Efficient Logistics

In any warehouse, regardless of its size, effective space and product management hinges on good organization. Labeling is one of the fundamental elements of smooth, error-free warehouse operations. Correctly labeled flap boxes are easier to identify, which speeds up retrieval and reduces the risk of mistakes during order picking. Good practices in documentation and labeling can significantly streamline inventory handling, enhance overall warehouse efficiency, and impact logistical costs, as we discussed in the article: Flap box and shipping costs – how does packaging affect expenses?

Below are the most important rules concerning the labeling of flap boxes:

- Labels – Clear, Front and Center

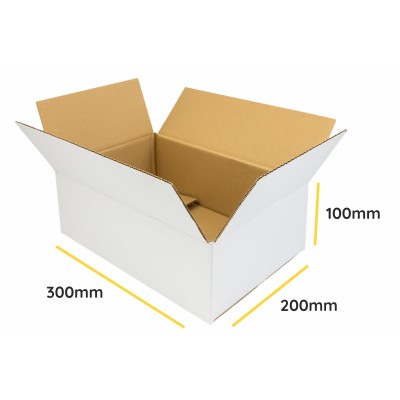

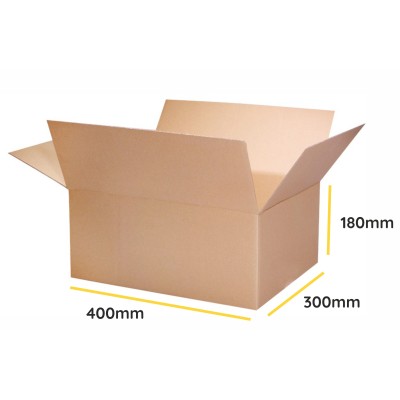

Labels are the basic method of identifying boxes. Ensure they’re easy to read and contain unambiguous information. Consider including:- Box Size – helps determine where it’s best stored.

- Receiving Date – indicates when the item arrived in the warehouse, vital for inventory rotation (e.g., FIFO principle).

- WMS (Warehouse Management System) – A warehouse management system is an increasingly common solution revolutionizing how goods are stored and tracked. Benefits of WMS implementation include:

- Accurate Location – each box is assigned an exact position in the warehouse, reducing retrieval time.

- Real-time Stock Monitoring – the system keeps track of how many boxes you have, aiding in planning and reordering.

Proper labeling and employing a WMS system not only speeds up work in the warehouse, but also helps avoid issues with shipping errors and logistical mix-ups.

Staff Training – Foundation for Effective Storage and Carton Protection

Efficient warehouse management and flap box storage isn’t just about tools or procedures—people are the critical factor in ensuring the quality and longevity of stored packaging. Warehouse workers are the frontline defense against logistical errors, damage, or product destruction.

For warehouse operations to remain efficient and aligned with best practices, continuous staff training is essential. It should cover proper carton handling, correct stacking and space organization, along with methods for quality control and detecting damage.

Warehouse standards such as ISO 9001 began evolving in the 1980s, laying the groundwork for modern quality management across various industries worldwide.

Summary

Optimal storage of flap boxes is crucial to ensuring their longevity and functionality. Key practices include maintaining proper storage conditions—monitoring temperature, humidity, and ventilation—together with effective warehouse management, protection against pests, and correct labeling of boxes, which facilitates quick identification and minimizes logistical errors.

FAQs, or Frequently Asked Questions

- Should boxes be stored flat or assembled?

It’s best to store new boxes flat. Doing so saves space, helps prevent damage, and makes them easier to prepare for future use. - What risks come with improper box storage?

Improper storage can lead to deformation, moisture problems, or even mold growth. This affects not only the packaging but also the products stored inside. Thus, it’s not advisable to keep flap boxes in basements. - Which flap box materials are best for warehouse storage?

High-quality flap boxes made of durable corrugated board provide excellent shock and damage resistance. Choosing the right carton also depends on the nature of the products being stored—fragile items may require stronger cartons.