Folding carton and transport costs - how do packaging affect expenses?

Contents:

- Key Points

- Folding Carton and Savings – A Recipe for Efficient Logistics

- How Does Packaging Affect Transportation Costs?

- How to Optimize the Choice of Cartons and Avoid the Most Common Packaging Management Errors?

- Match the Carton Dimensions to the Contents

- Using Cartons with Appropriate Strength

- Use of Standard Carton Dimensions

- Errors That Cost...

- Summary

- FAQs, or Frequently Asked Questions

Packaging plays an essential role in organizing transport and logistics. Properly selected folding cartons can significantly reduce delivery costs, improve warehouse process efficiency, and also enhance customer satisfaction. What criteria should be considered when choosing packaging to optimize transportation costs and avoid unnecessary expenses?

Key Points

- Selecting cartons with the appropriate strength ensures the safety of the goods without incurring unnecessary expenses on overly robust packaging.

- Using packaging in standard sizes facilitates the automation of the sorting process and better utilization of space in warehouses and transport vehicles.

- Properly matching the carton to the size of the product reduces wasted space and eliminates the need for unnecessary fillers, thereby lowering transportation costs.

Folding Carton and Savings – A Recipe for Efficient Logistics

It can confidently be said that folding carton is the basic packaging in the world of transport. Made of corrugated cardboard, it stands out with its simple design that, when assembled, creates a stable and durable box. Thanks to its advantages, folding cartons are used in many industries – from e-commerce to heavy industry.

Advantages of Folding Cartons:

- Versatility – ease of adaptation to various types of products.

- Low weight – which translates into lower transportation costs.

- Ease of storage – delivered flat, they take up little space.

- Recyclability – folding cartons meet the growing ecological requirements.

Of course, these are just some of the advantages of folding cartons – their properties and intended use mainly depend on the type of cardboard from which they are made. We discussed this in more detail in the article: What are the types of folding cartons and what are they used for?

It is also worth noting that despite excellent logistical predispositions, improper use of them may lead to an increase in both direct and indirect costs. How so?

How Does Packaging Affect Transportation Costs?

1. The Impact of Package Dimensions on Carrier Costs

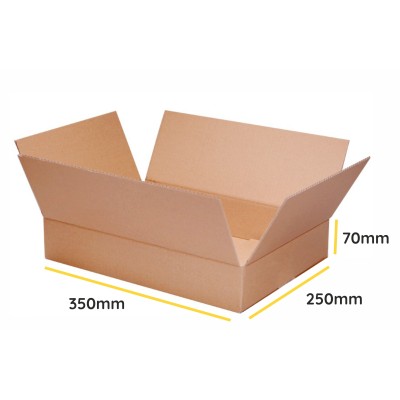

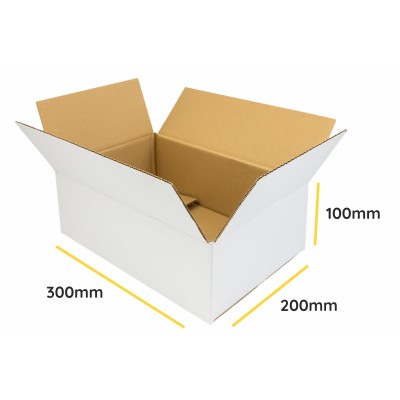

Leading carriers use price lists based on the dimensions and weight of shipments. In the case of cartons that are too large in relation to their contents, a dimensional weight is charged, often higher than the actual weight.

For example, for shipments to collection points, each package must fit within specified dimensions that are adjusted to the requirements of automated parcel collection devices. Example dimensional limits are:

- Size A: 8 × 38 × 64 cm, up to 25 kg.

- Size B: 19 × 38 × 64 cm, up to 25 kg.

- Size C: 41 × 38 × 64 cm, up to 25 kg.

2. Costs Arising from Wasted Space

Improperly selected carton dimensions can lead to inefficient use of space in transport vehicles. As a result:

- The vehicle carries fewer shipments per trip.

- Unit transportation costs increase.

3. Package Weight and Shipping Costs

Heavier packaging generates higher transportation costs, which is why it is so important to use materials that are lightweight yet durable. Corrugated cardboard, used in the production of folding cartons, is available in various weights, allowing for the selection of an optimal solution where the safety and protection of the contents is a priority.

How to Optimize the Choice of Cartons and Avoid the Most Common Packaging Management Errors?

Since properly selected packaging can contribute to significant savings, while an improper choice generates additional expenses and complications, what should you particularly pay attention to when selecting packaging?

Match the Carton Dimensions to the Contents

One of the most important aspects when choosing a carton is its proper fit to the size of the product being shipped. An oversized carton not only wastes space but also incurs unnecessary costs that may arise at various stages of transport and storage.

- Fillers: An oversized carton usually requires additional filling materials, such as bubble wrap or paper fillers, which increase the weight of the package. Extra weight can lead to higher transportation costs, especially if the carrier charges based on weight.

- Dimensional Charges: Carriers, especially those using parcel locker systems or other automated collection points, charge fees based on the package dimensions. An oversized carton that does not match the actual contents may result in a charge for excessive dimensions, which is not beneficial for the customer.

Using Cartons with Appropriate Strength

The second equally important factor is the proper strength of the packaging.

- Cartons with Insufficient Strength may not provide adequate protection, especially for heavier shipments or delicate products. Damage to the goods leads to the need for their replacement or repair, which increases operational costs.

In other cases, customers try to compensate for the weak strength of the cartons by adding extra layers of stretch film or sealing with tape – which may improve the temporary stability of the shipment, but does not solve the issue of basic product protection and results in unnecessary wastage of protective materials. - Overly Strong Cartons can, on the other hand, represent an unnecessary expense. Often, the choice of stronger packaging results from a desire to ensure maximum protection, but in the case of less delicate products, an overly robust carton is not cost-effective. In such cases, it is better to opt for optimal cardboard that provides adequate protection while minimizing costs.

Use of Standard Carton Dimensions

Another aspect that can help reduce transportation costs is the use of standard carton dimensions. Courier companies and carriers prefer packaging in standard sizes because it facilitates the automatic sorting of packages and allows for optimal use of space in warehouses and transport vehicles.

Errors That Cost...

Below we present the most common mistakes that can negatively affect operational efficiency and increase costs in companies engaged in trade and logistics. In addition, they can affect the efficiency of the entire supply chain and even the perceived quality of services by customers.

- Lack of Packaging Standardization – Companies that have not introduced standardization in carton selection often use various sizes and types of packaging depending on the product type. The absence of a unified packaging selection system can lead to problems in storage and transportation.

Additionally, human error comes into play – employees, when selecting different cartons for the same product, may unknowingly waste space, use too many fillers, or improperly secure the goods. Standardizing cartons allows for better organization and reduced storage costs. - Improper Storage of Cartons – Storing cartons in an improper manner, for example in a humid room or in places exposed to external factors, can lead to their damage and loss of strength. Improperly stored folding cartons can easily become deformed, which will affect their ability to protect the goods. As a result, this may lead to the need for using more fillers or, worse, to product damage during transport.

- Infrequent Reviews and Updates of Cartons – Some companies do not conduct regular reviews and updates of the packaging they use. Due to changing carrier regulations, an increase in order volume, or market requirement changes, it may turn out that the cartons previously used no longer perform their functions optimally. Regularly adjusting the selection of cartons to the company’s current needs is key to optimizing transportation costs.

The size of the carton not only affects transportation costs but also the environment. According to studies, reducing the packaging size by just a few centimeters can decrease CO2 emissions related to transport by as much as 10%.

Summary

Properly matching the carton to the product, choosing the right strength, and using standard dimensions allow for a significant reduction in costs associated with transport and storage. Companies that neglect these issues expose themselves to additional expenses resulting from wasted space, excessive dimensional charges, and product damage. Regular analysis and standardization of packaging are key to optimizing costs and efficient logistics management.

FAQs, or Frequently Asked Questions

- What are the differences between folding cartons and other types of packaging? Folding cartons offer a range of benefits, such as ease of storage (delivered flat) and low weight, which reduces transportation costs. Compared to packaging made from other materials, such as bubble wrap or plastic, cartons are more environmentally friendly and often cheaper to produce.

- What strategies help minimize packaging-related costs? To reduce packaging costs, it is advisable to standardize cartons, tailor them to specific products, and regularly analyze changing transportation requirements. This approach allows for savings both in storage and during transport.

- Which folding cartons are best for international transport? For international transport, it is best to choose cartons with higher strength and appropriate dimensions that meet the requirements of international carriers. It is also important that the cartons comply with standards for moisture and mechanical damage protection.