How to choose the right flap cardboard for storage and transport?

Contents:

- Key points

- Flap box – a partner for transport, warehousing, and storage

- Size matters – how to match box dimensions to the contents?

- Cardboard thickness and quality – what’s worth knowing?

- The box’s spaciousness versus warehouse space – how to adapt the box to the available area?

- Summary

- FAQs – frequently asked questions

Choosing the right flap box is a key factor that ensures safety and convenience when transporting and storing a variety of products. Whether it’s about moving house, shipping goods, or organizing warehouse space, a suitable box protects the contents from damage and makes the logistics process more efficient. In this article, we present what to pay attention to when selecting a flap box.

Key points

- The choice of the correct cardboard thickness depends on the weight and fragility of the items. The heavier and more delicate the goods, the thicker the box should be to provide optimal protection.

- Thanks to their design, flap boxes take up less space in storage when folded flat. It’s important to choose the correct box size so it fits standard shelf dimensions, which allows for efficient use of available space.

- In addition to the basic structure of the box, it’s worth considering the use of extra protective materials such as bubble wrap, foam inserts, or corner protectors.

Flap box – a partner for transport, warehousing, and storage

Flap boxes are among the most commonly chosen packaging solutions in logistics because they suit a wide range of products and can be used in various industries such as e-commerce, the food industry, electronics, the chemical industry, and many more. Their versatility makes them an ideal solution for diverse needs, which is why they are a very popular choice in logistics and warehousing.

What’s more, due to their design, flap boxes are easy to store and transport when folded flat. They take up little space, making warehouse organization more flexible and less costly, especially where space is limited.

Another advantage of flap boxes is their ability to protect stored goods. Thanks to their sturdy construction, a flap box provides adequate protection against mechanical damage, dust, dirt, and other contaminants. This is crucial both during transport and while items are in storage, where products often need to be stored for longer periods under various conditions. But that’s not all.

Flap packaging is relatively inexpensive to manufacture compared to other materials such as plastic or wood. With a wide range of available sizes, flap boxes are a cost-effective solution that helps reduce the expenses associated with transportation and storage of goods.

Having analyzed the advantages of flap boxes, let’s now focus on one of the key aspects of selecting them – the right size, which greatly impacts logistics efficiency and content protection.

Size matters – how to match box dimensions to the contents?

To begin, let’s emphasize the most important aspects: A box that’s too small may damage the contents by putting too much pressure on them, while one that’s too large will allow items to shift around, increasing the risk of damage. So how do you choose the right box size?

- Measure your items:

Accurate dimensions are key. Measure the length, width, and height of the items to be boxed, and choose a package that’s a few centimeters larger to allow for filling materials. - Avoid “shipping air”:

The box shouldn’t be too big for its contents. Too much free space means additional shipping costs and increased use of materials to fill the empty areas. - Use fillers:

Remember, for fragile goods, it’s always a good idea to leave room for fillers that provide extra protection against shocks and damage – Boxmarket boasts a huge selection of protective materials that perfectly suit various packing needs.

In addition to traditional bubble wrap, we also offer PE foam spacers, cooling inserts, specialized inserts for shipping wine bottles, protective corners, corrugated cardboard, and many other solutions that ensure proper protection for your products. - Standard box sizes:

If you’re using shipping services, choose boxes that adhere to their standards to avoid additional charges for non-standard packaging.

Cardboard thickness and quality – what’s worth knowing?

Right after size, the thickness of the cardboard plays a key role. The appropriate choice of flap box depends on the weight and fragility of the item being shipped. The heavier and more delicate an item is, the thicker and sturdier the cardboard should be.

- Single-wall cardboard – This is the thinnest and lightest form of corrugated cardboard, consisting of one layer of fluting. It’s used for packing lightweight items that don’t require special protection against mechanical damage. Single-wall is perfect for packing books, clothing, documents, food items, or other products that don’t subject the packaging to heavy loads.

- Triple-wall cardboard – Consists of three layers of fluting. It works well for packing medium-weight products that need solid protection against mechanical damage. It’s used for transporting electronics, household appliances, furniture, or other items that may be exposed to bumps and impacts. It offers greater stability and better resistance to compression, crucial when shipping more fragile products.

- Five-layer cardboard – This is one of the most durable types of corrugated cardboard, consisting of five layers. Thanks to its structure, it offers very high resistance to mechanical damage and heavy loads, making it ideal for packing heavy objects. Five-layer cardboard is used for transporting large machines, household appliances, building materials, or industrial products that require special protection.

There are also cardboards with more layers, used for protecting very heavy items such as machinery or large structural components that require exceptional resistance to shocks, compression, and other harsh transport conditions.

Naturally, the world of flap boxes is very diverse, especially regarding durability and the material used. You can read more details on this in the article: What types of flap boxes exist and what are they used for?

Seven-layer cardboard is an uncommon, highly durable solution that provides excellent protection against mechanical damage, shocks, and moisture. It’s mainly used for packing heavy items like machinery or household appliances.

The box’s spaciousness versus warehouse space – how to adapt the box to the available area?

What if we want to choose boxes for warehouse use or storage rather than for typical shipping? Good planning and basic knowledge of flap box properties matter here as well. Boxes that are too large will take up more space on shelves, making them harder to store and increasing storage costs. That’s why it’s worth choosing a box that fits the available space, for example:

- Match the box to shelves and racks: Warehouses typically use standard shelf and rack sizes, so it’s wise to pick a box that fits these dimensions to make the most of available space.

- Optimize layout: Boxes should be easy to stack, store securely, and remove. Choose dimensions that allow efficient placement of boxes on pallets or racks.

- Pay attention to coatings: If boxes will be stored in warehouses with changing conditions, consider using flap boxes with a waterproof coating or cardboard that has heightened moisture resistance. This way, even in humid environments, the contents remain well protected. Also, keep an eye on material durability so the boxes can withstand repeated handling and long-term storage.

Summary

Choosing the right flap box is crucial for both transporting and storing goods. It’s important to select the appropriate size and cardboard thickness, and to use fillers, which ensures protection and helps minimize costs. Single-wall, triple-wall, and five-layer cardboards differ in strength, letting you match the box to the type of goods being shipped or stored.

A properly chosen flap box also helps organize warehouse space, especially where room is limited. Remember to account for transportation requirements as well and select flap packaging with additional protective coatings if needed.

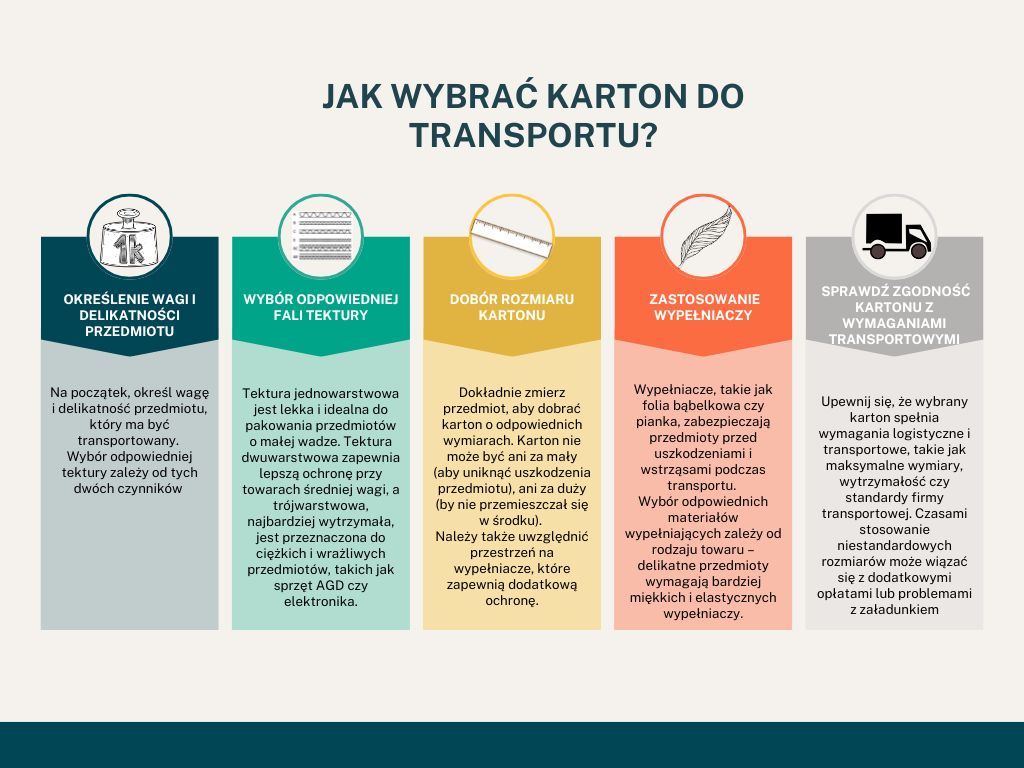

The following diagram will help you organize the most important steps

FAQs – frequently asked questions

- Are flap boxes eco-friendly?

Yes, flap boxes are fully biodegradable and recyclable, making them a more environmentally friendly alternative compared to plastic packaging. Additionally, many flap boxes are produced from recycled cardboard, further reducing their environmental impact. - Are flap boxes available in different colors?

Yes, flap boxes come in various colors, including natural brown as well as white or printed options, which can be important for companies that want to reinforce their visual identity or maintain an aesthetic look for their packaging. - Can I use flap boxes in low temperatures?

Yes, flap boxes work well in cold conditions. However, if you’re storing them in extremely cold or humid environments, pay attention to selecting a cardboard with enhanced moisture resistance or additional protective layers to safeguard goods from damage.