What are the most common mistakes when using flap boxes and how to avoid them?

Contents:

- Key points

- How to avoid costly mistakes when packing flap cardboard boxes?

- Choosing the wrong box size

- Insufficient protection of the contents

- Poor sealing of the box

- Packing items that are too heavy in flap cardboard boxes

- Incorrect storage of boxes before use

- Lack of proper labeling and marking

- Improper box folding

- Nothing lasts forever—how many times can one box be used?

- Summary

- FAQs – frequently asked questions

```html

Improper use of flap cardboard boxes can lead to a number of problems, such as damage to the contents, increased transportation costs, or difficulties with storage. In this article, we present the most common mistakes made during packing and suggest how to avoid them in order to optimize the packing and transportation process.

Key points

- Choosing a box with the right dimensions is a priority for the safety of the contents and packing efficiency.

- Properly filling the space with protective material and securely sealing the box with tape minimizes the risk of damage during transport.

- Boxes should be stored in a dry, cool place, protected from moisture and extreme temperatures, so they maintain their durability.

How to avoid costly mistakes when packing flap cardboard boxes?

Mistakes and slip-ups when packing flap cardboard boxes have probably happened to everyone who has dealt with shipping or storing goods at least once. Although at first glance they may seem insignificant, in fact they can have catastrophic consequences. Depending on the type of mistake, the shipping bill can far exceed our expectations, and the goods may not reach the recipient in one piece. Below are a few mistakes that cause these difficulties.

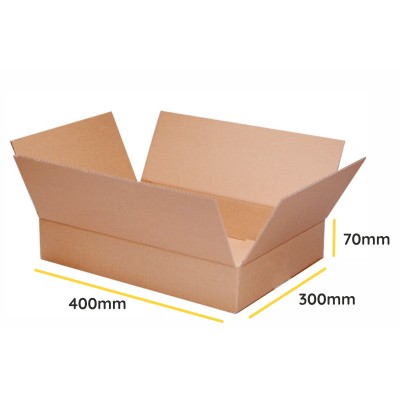

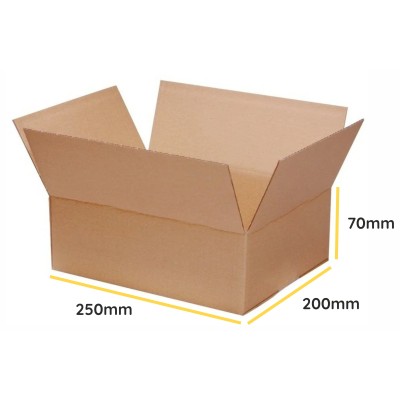

Choosing the wrong box size

Selecting a box that is not the right size is one of the most common packing problems. A box that is too small may not accommodate all items, while a box that is too large may create unnecessary free space that requires additional fillers.

How to avoid this mistake?

To choose the right flap cardboard box, start by measuring the items you want to pack. Remember that the box should have enough room to allow effective filling of the space with protective material, such as bubble wrap or packing paper. Avoid placing large items in boxes that are too small, as this can lead to damage during transport. But what if your shipment is an unusual size? At BoxMarket, we offer flap cardboard boxes made to measure, providing excellent protection for your products while eliminating unnecessary costs.

Insufficient protection of the contents

Securing the contents of the box is a crucial step that is often underestimated. Many people skip this step or use too little protective material, which can result in damage to items during transport. Sometimes they also use “home substitutes,” such as old cloths, clothing, or rolled-up shopping bags, which not only affect the appearance of the shipment but also increase the risk of damage.

How to avoid this mistake?

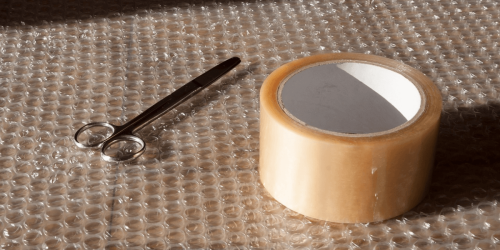

Always use appropriate protective materials, such as bubble wrap, packing paper, fillers (e.g., polystyrene beads), or cardboard inserts. Fill the free spaces in the box so that the items cannot move around during transport. Well-packed products minimize the risk of damage, which translates into greater security for your shipments.

Poor sealing of the box

Improper or insufficient sealing of the box is another common problem. Inadequate sealing can cause the package to come apart during transport, especially if it is exposed to shocks or bearing weight. If you don’t want your item to “unpack itself” before it reaches the recipient, be sure to follow the tip below.

How to avoid this mistake?

A flap box should be carefully sealed using the right packing tape. It is important to use a tape of sufficient strength, preferably intended for packing. You should seal the box along all edges and at the seams, ensuring that the tape is applied continuously and securely. If the box is heavy or subject to large loads, you may consider additional reinforcement of the seams, for example, with special strapping tapes.

For additional content protection, it may be worthwhile to wrap the flap packaging with stretch film—eco-friendly equivalents are just as durable as synthetic ones, while support recycling and sustainable solutions in the world of flap cardboard boxes.

Packing items that are too heavy in flap cardboard boxes

Flap cardboard boxes have their load capacity limits. Exceeding these limits can tear the box and result in damage to its contents or transport issues.

How to avoid this mistake?

Before packing, check the load capacity parameters of a particular box, which are usually provided by the manufacturer. For very heavy items, it is advisable to use specialized reinforced boxes or to provide additional protection by distributing the weight into several boxes. Also remember not to exceed the permissible box weight and to ensure that the load is evenly distributed.

The box’s construction, the number of layers, and the production method also affect the durability of flap cardboard boxes. We covered this topic in one of our previous articles: What are the types of flap cardboard boxes and what are they used for?

Incorrect storage of boxes before use

Flap boxes, like any other packaging material, require appropriate storage. The wrong location, moisture, or excessive sun exposure can affect their quality and durability.

How to avoid this mistake?

A flap cardboard box should be stored in a dry place

, protecting it from moisture and extreme temperatures. Ideally, the packaging should be kept indoors, away from direct sunlight. Also avoid storing the boxes on moist surfaces, as this can lead to deformation and weakening of the structure.

Lack of proper labeling and marking

Another common problem is the lack of proper labeling of boxes, which can lead to misunderstandings during transport or storage. Failing to indicate the contents or provide warning labels can result in damage. Sometimes a courier, without clear markings such as “fragile,” may handle the package less carefully, increasing the risk of damage.

How to avoid this mistake?

Each box should be properly marked with a label indicating its contents, the sender’s and recipient’s addresses, and any special requirements, e.g., “FRAGILE” or “THIS SIDE UP.” It is also a good idea to include information on the maximum load the box can withstand. Additionally, be sure to choose labels suitable for weather conditions—use materials that resist moisture and temperature fluctuations, especially for shipments exposed to harsh transport conditions.

Moreover, choosing the right adhesive is key—labels must be well attached so they do not come off during transport. Also keep in mind that a smoother box surface will “adapt” to almost any sticker label, but boxes with a more corrugated or rough surface require special labels that adhere better to the uneven texture.

Some courier companies offer discounts for well-packed shipments, encouraging the use of suitable protective materials and labeling.

Improper box folding

Incorrectly folding boxes before use can lead to difficulties in storage and to potential damage during use.

How to avoid this mistake?

Before folding the box, make sure all edges are properly creased. Fold the box according to the manufacturer’s instructions to maintain its durability. Remember to avoid folding boxes in places prone to heavy pressure or in damp conditions. Properly folded boxes will retain their longevity.

Nothing lasts forever—how many times can one box be used?

Often, when returning goods, we reuse the same flap cardboard boxes in which we received the packages, assuming their structure is sufficiently solid for another trip. Although such boxes may withstand one or two shipments, their durability decreases significantly after a few journeys—each additional use reduces rigidity, and the edges may become damaged.

Packaging that has been used multiple times often no longer performs its original function, and though it may appear sturdy, its ability to withstand further shocks, weight, or pressure can be limited.

At Boxmarket, we offer boxes with exceptional durability, designed for multiple uses and proper storage conditions. Nevertheless, like any packaging, their lifespan depends on how they are treated during storage, use, and the packing process itself.

Summary

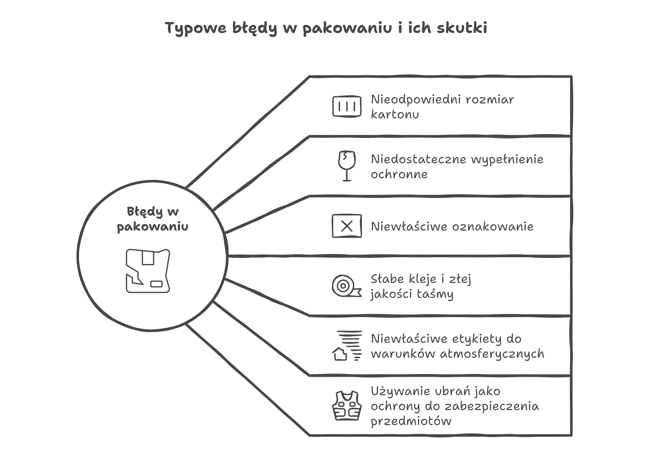

Errors in using flap cardboard boxes can have serious consequences, such as damage to shipment contents, delivery delays, or higher shipping costs. Incorrect sizing, lack of proper protection or labeling, and poor storage can reduce its efficiency and safety.

By taking a deliberate approach to every stage of packing, from choosing the box to labeling it, you can minimize the risk of damage and unnecessary expenses.

FAQs – frequently asked questions

- What are the differences in flap cardboard boxes with different cardboard thicknesses?

Boxes made from thinner cardboard are lighter and cheaper but less durable, so they are suitable for shipping lighter products. Thicker cardboard provides greater resistance to damage and shocks, making it ideal for packing heavier or more delicate products. - Can I reuse flap cardboard boxes multiple times?

Yes, but remember that reusable boxes lose their durability over time, especially after a few trips. Old boxes may not fulfill their function, increasing the risk of damaging the contents. It is worthwhile to check the condition of the box before reusing it, particularly if it has been used several times already. - What are the weight limits for flap cardboard boxes?

Each box has a specified load capacity, depending on its construction and material. It is important not to exceed the maximum weight the box can hold. Overloading can cause the box to tear, leading to damage of its contents. Always follow the manufacturer’s guidelines on maximum load. If you are unsure which box is suitable for your shipment, the Boxmarket staff will be happy to help you choose the right flap cardboard box for your item.

```