Brown flap cardboard K020 BC 600x400x400

from 11.57 zł tax incl.

| Quantity | Price tax incl./tax excl. |

|---|---|

| > 1 szt. | 0.48 zł 0.39 zł |

| > 100 szt. | 0.47 zł 0.38 zł |

| > 200 szt. | 0.44 zł 0.36 zł |

| > 300 szt. | 0.43 zł 0.35 zł |

| Package | 0.38 zł 0.31 zł |

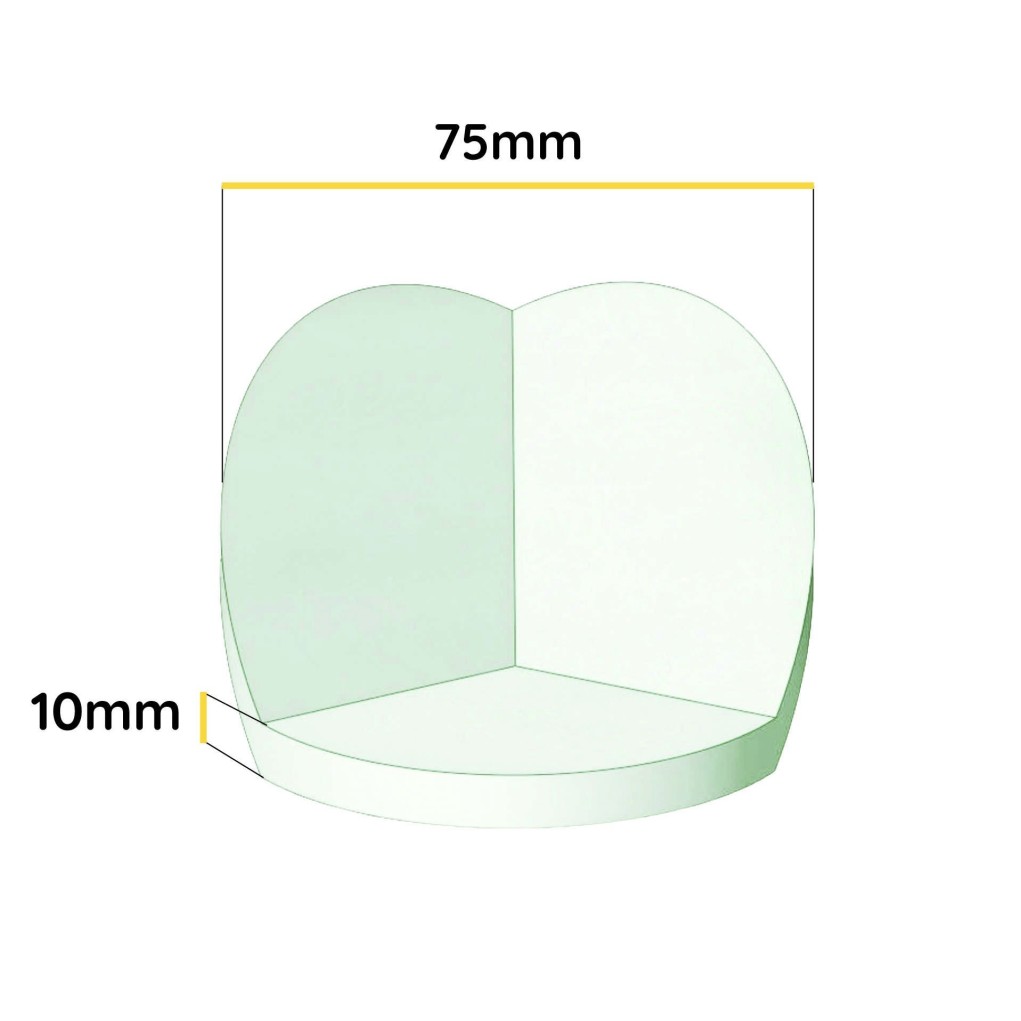

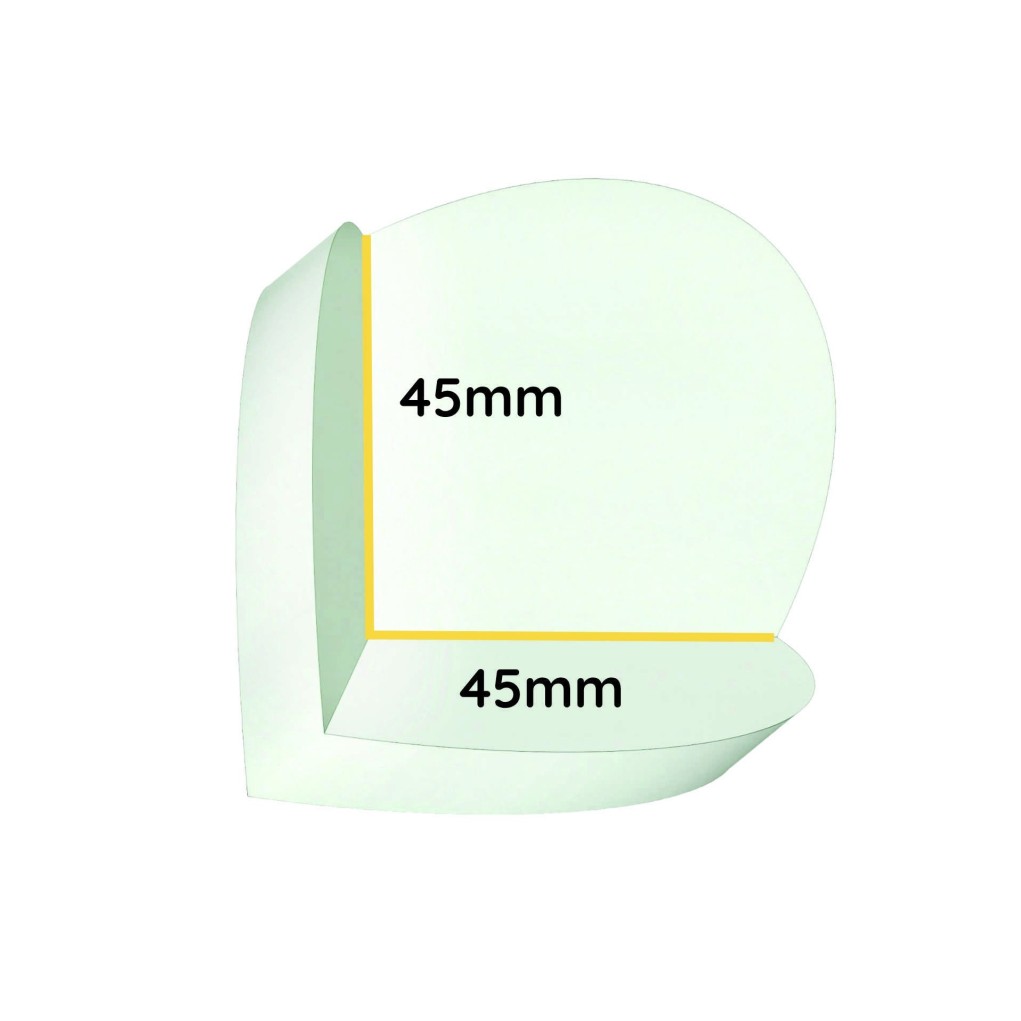

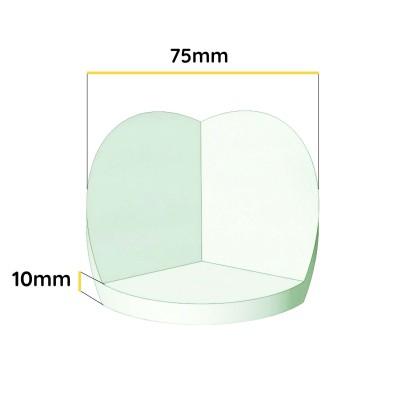

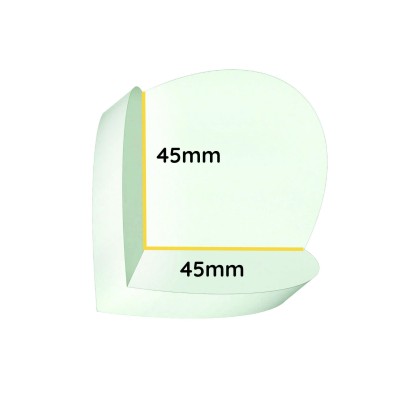

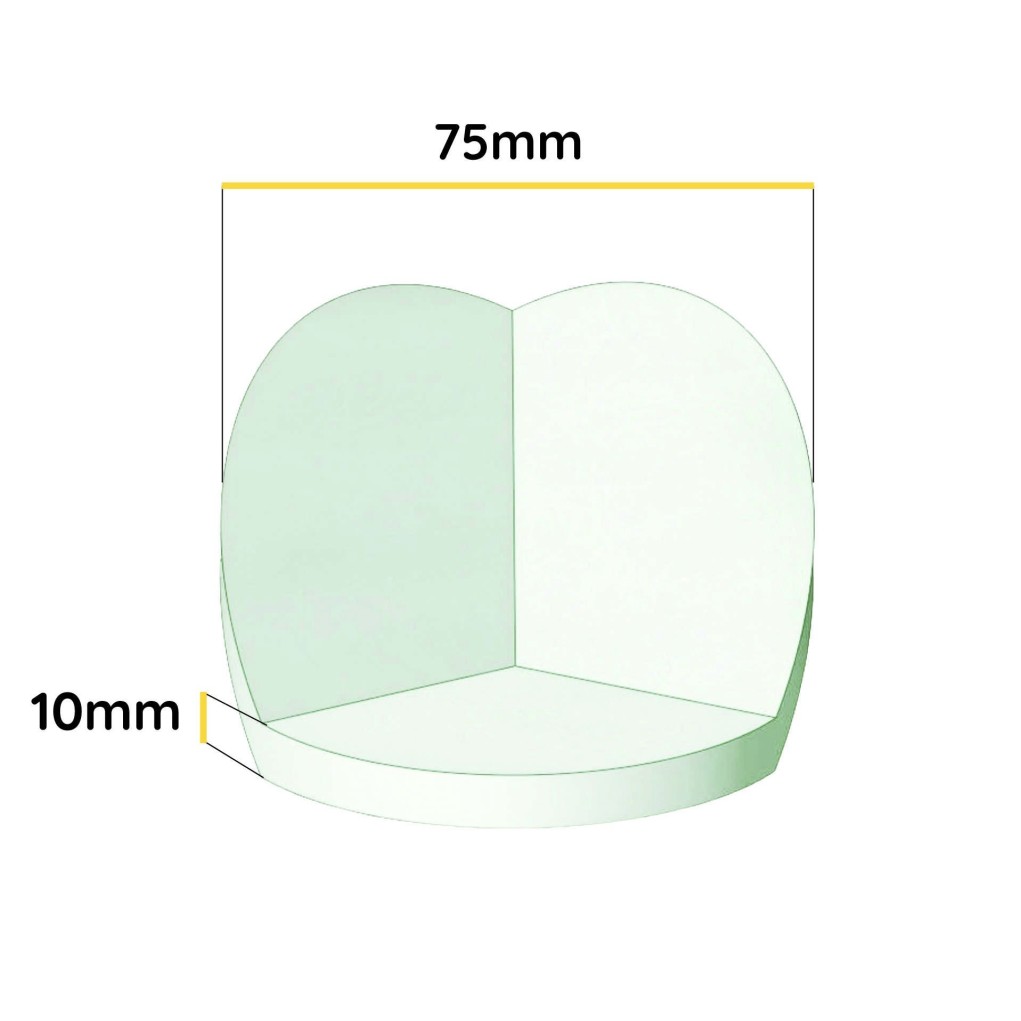

10 mm of resilient polyethylene foam, formed in the shape of an “L”, creates a barrier protecting the most vulnerable places of your product during transport. The Cut-Corner type protective corner is an innovative solution guaranteeing excellent protection for delicate edges and corners of packed items. Thanks to a specially designed profile, it easily provides optimal immobilization and cushioning – even when the package falls or suffers a strong shock, the contents remain safe. It is an indispensable element of protection when shipping electronics, furniture, glass and all valuable products, where every corner requires special attention 🛡️.

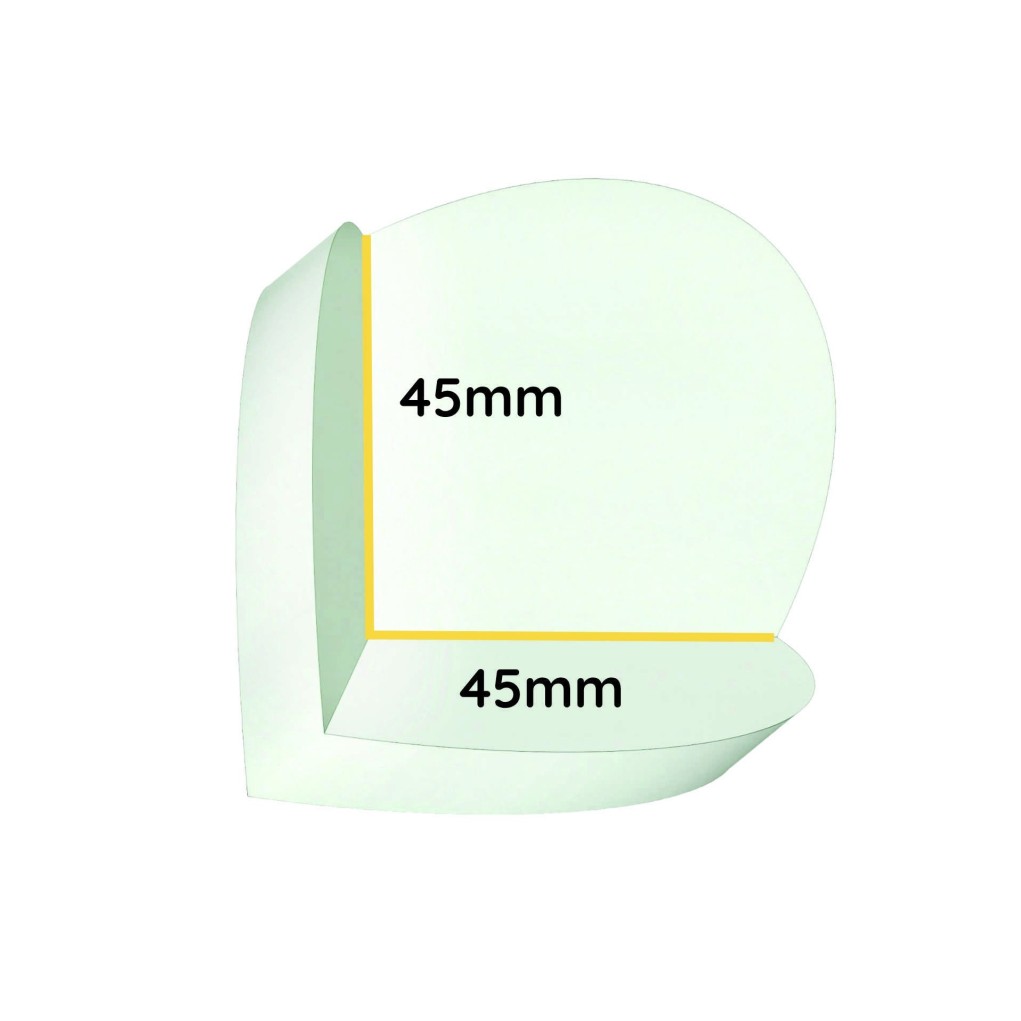

The Cut-Corner protective corner is a three-dimensional foam profile in the shape of a right angle, which is placed on the edge of an object, protecting both adjacent surfaces and the corner itself. Its internal recess with dimensions of ~45 × 45 mm perfectly encloses the corner of the product, and the 10-millimeter foam walls act like a shield absorbing impact energy. The special "cut" shape of the corner (hence the name Cut-Corner) makes the element fit well to the edge and does not fall off during packing or transport. As a result, even sensitive, delicate items with sharp or protruding edges gain solid protection against crushing, bumping or chipping.

Such foam corners are among the most popular protective fillers in transport packaging. They are a simple, but very effective way of securing critical points of goods - just put them on all four (or eight) corners of the product to create a distance from the walls of the box and cushion any shocks. This way, transported devices, decorative or structural elements reach their destination in an undamaged condition, without scratches, dents or cracks 🎯.

Cut-Corner corners are made of foamed polyethylene (PE), which belongs to the group of low-density materials (LDPE). The foaming process gives the material the form of a light foam with a closed cell structure - this means that the interior is made up of millions of air bubbles trapped in flexible polyethylene walls. Such construction translates into exceptional user features: the foam is ultra-light, elastic and resistant to external factors. Unlike styrofoam, PE foam does not crumble or dust, ensuring cleanliness at the packing place and aesthetics of the delivered goods.

The LDPE granulate with the addition of a foaming agent is extruded into the shape of the letter "L", creating a lightweight profile with closed air cells. After cooling, the profile is cut into 75 mm sections, and precision cutters give the recess ~45 × 45 mm. Each corner undergoes quality control, after which it goes to packing and shipping 🚀.

The Cut-Corner corner is designed for multiple use; after 100% wear, it can be recycled – LDPE 4 code. Ground up, it returns to the cycle as polyethylene regranulate, contributing to a closed-loop economy. During combustion in professional power installations, PE does not emit toxic gases, which further minimizes the impact on the environment. By choosing foam corners instead of brittle styrofoam elements, you reduce waste and limit product losses resulting from damage, supporting sustainable development goals ♻️.

Match the custom-sized box to the Cut-Corner corners – you will get a perfect duo of protection and aesthetics.

Also available foam sheets 10 / 20 / 30 / 40 / 50 mm – ask about non-standard formats.

Use the %%%p:1021:interactive creator%% – enter the sheet dimensions, choose a thickness of 10–50 mm and a color (white or black); you will see the price immediately.

Are you planning to send large volumes or introduce corners into your packing line? Contact us – we will prepare a pallet offer for Cut-Corner corners and help you choose the perfect size, density and color of PE foam tailored to your logistics processes.

from 11.57 zł tax incl.

from 11.81 zł tax incl.

from 7.06 zł tax incl.

from 7.06 zł tax incl.

from 3.33 zł tax incl.

from 12.41 zł tax incl.

from 68.87 zł tax incl.

from 6.14 zł tax incl.

from 1.25 zł tax incl.

from 153.69 zł tax incl.

from 33.47 zł tax incl.

from 4.17 zł tax incl.

from 49.82 zł tax incl.

from 68.87 zł tax incl.

from 42.00 zł tax incl.

from 11.05 zł tax incl.

from 11.29 zł tax incl.

from 22.95 zł tax incl.

from 1.27 zł tax incl.

from 13.12 zł tax incl.

check_circle

check_circle

Please verify the country of delivery and form of purchase in the customer panel. The data provided in the customer panel differs from the currently set data.

Change settingsWe have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.

We have changed the quantity to what is available in stock.